List of small modular reactor designs

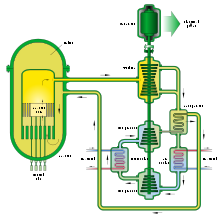

[57][58] It is a fully integrated reactor module with an internal coolant system, with a two-year refuelling interval, producing 385 MWt and about 125 MWe.

The primary coolant system uses natural circulation, so there are no pumps required, which provides inherent safety against core meltdown, even in accident situations.

[64] Currently, the first reactor of the type is being built near the city of Zárate, in the northern part of Buenos Aires province.

The Copenhagen Atomics Waste Burner is a single-fluid, heavy water moderated, fluoride-based, thermal spectrum and autonomously controlled molten salt reactor.

Pb has a higher boiling point than the other commonly used coolant metal, sodium, and is chemically inert with air and water.

The fuel is either U–Zr or U–Pu–Zr, and can keep the reactor at full power for 15 years before needing to be refueled, with either 239Pu at 11% or 235U at 13% It requires on-site storage, at least until it cools enough that the coolant solidifies, making it very resistant to proliferation.

[68] Assembly line construction is planned, producing "mobile units that can be dispersed throughout the country where they need to go to generate the power."

[70] Its potential applications include direct replacement of supercritical coal-fired power plants,[71][72] while its heat could be used for seawater desalination, hydrogen production, or a wide range of other high temperature uses in industry.

[73] A commercial version of a Los Alamos National Laboratory project, the Hyperion Power Module (HPM) is a LMR that uses a Pb–Bi coolant.

[77] Developed by an international consortium led by Westinghouse and the nuclear energy research initiative (NERI), IRIS-50 is a modular PWR with a generation capacity of 50 MWe.

[74][78] Based on the design of nuclear power supplies for Russian icebreakers, the modified KLT-40 uses a proven, commercially available PWR system.

The coolant system relies on forced circulation of pressurized water during regular operation, although natural convection is usable in emergencies.

On 14 September 2019, it arrived to its permanent location in the Chukotka region where it provides heat and electricity, replacing Bilibino Nuclear Power Plant, which also use SMR, of old EGP-6 design, to be shut down.

The nuclear steam supply systems (NSSS) for the reactor arrive at the site already assembled, and so require very little construction.

Each reactor module would produce around 180 MWe, and could be linked together to form the equivalent of one large nuclear power plant.

[83][84] In March 2017 the development project was terminated, with Bechtel citing the inability to find a utility company that would provide a site for a first reactor and an investor.

[90][91] OPEN100 is an SMR project developed by the Energy Impact Center that has published the first open-source blueprints for a 100 MWe pressurized water reactor.

[93] The Pebble Bed Modular Reactor (PBMR) is a modernized version of a design first proposed in the 1950s and deployed in the 1960s in Germany.

It uses spherical fuel elements coated with graphite and silicon carbide filled with up to 10,000 TRISO particles, which contain uranium dioxide (UO2) and appropriate passivation and safety layers.

The NMR would require temporary on-site storage of spent fuel, and even with the modular design would need significant assembly.

[98] With its ability to be sited away from a water source and a footprint approximately the size of a football field it is targeted towards distributed energy users.

[100] Recently Last Energy announced $19 Billion worth of deals in Europe[101] after constructing their demonstration unit in Texas.

The helium coolant doesn't interact with the structural metals or the reaction, and simply removes the heat, even at extremely high temperatures, which allow around 50% efficiency, whereas water-cooled and fossil fuel plants average 30–35%.

The design relies on a moveable neutron reflector to maintain a steady state power level for anywhere from 10 to 30 years.

[118] It represents a breakthrough in molten salt reactor technology, with the potential to make nuclear power safer, cheaper and cleaner.

The modular nature of the design, including reactor core and non-nuclear buildings, allows rapid deployment on a large scale.

Materials challenges are also greatly reduced through the use of standard nuclear certified steel, with minimal risk of corrosion.

The SSR wasteburning variant SSR-W, rated at 300 MWe, is currently progressing through the Vendor Design Review (VDR) with the Canadian Nuclear Safety Commission (CNSC).

The idea is that the slow breeding and burning of fuel would move through the core for 50 to 100 years without needing to be stopped, so long as plenty of fertile 238U is supplied.

NuScale's VOYGR SMR plant is a "modular" system designed to easily scale from small to medium commercial applications.