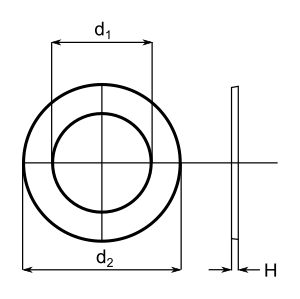

Washer (hardware)

High-quality bolted joints require hardened steel washers to prevent the loss of pre-load due to brinelling after the torque is applied.

Washers are also important for preventing galvanic corrosion, particularly by insulating steel screws from aluminium surfaces.

A thrust washer is used when a rolling element bearing is not needed either from a cost-performance perspective or due to space restraints.

They could be used for sealing small holes, rust spots or removed pipe connections in water tanks or large cooking vessels.

Therefore, spring washers are ineffective on left hand threads and hardened surfaces [citation needed].

The teeth of the washer cut through surface oxides, paints or other finishes and provide a gas-tight conductive path.

[17] Lock washers, locknuts, jam nuts, and thread-locking fluid are ways to prevent vibration from loosening a bolted joint.

Type B is a series of flat washers with tighter tolerances where outside diameters are categorized as "narrow", "regular" or "wide" for specific bolt sizes.

The British Standard for Metric Series Metal Washers (BS4320), written in 1968, coined the term "form".