Sawmill

Modern sawmills use a motorized saw to cut logs lengthwise to make long pieces, and crosswise to length depending on standard or custom sizes (dimensional lumber).

Before the invention of the sawmill, boards were made in various manual ways, either rived (split) and planed, hewn, or more often hand sawn by two men with a whipsaw, one above and another in a saw pit below.

An early improvement was the development of a movable carriage, also water powered, to move the log steadily through the saw blade.

By 1900, the largest sawmill in the world was operated by the Atlantic Coast Lumber Company in Georgetown, South Carolina, using logs floated down the Pee Dee River from the Appalachian Mountains.

In the 20th century the introduction of electricity and high technology furthered this process, and now most sawmills are massive and expensive facilities in which most aspects of the work are computerized.

Besides the sawn timber, use is made of all the by-products including sawdust, bark, woodchips, and wood pellets, creating a diverse offering of forest products.

[2] Water-powered stone sawmills working with cranks and connecting rods, but without gear train, are archaeologically attested for the 6th century at the Byzantine cities Gerasa (in Asia Minor) and Ephesus (in Syria).

[3] The earliest literary reference to a working sawmill comes from a Roman poet, Ausonius, who wrote a topographical poem about the river Moselle in Germany in the late 4th century AD.

[4] Marble sawmills also seem to be indicated by the Christian saint Gregory of Nyssa from Anatolia around 370–390 AD, demonstrating a diversified use of water-power in many parts of the Roman Empire.

[6]: 84–85 Prior to the invention of the sawmill, boards were rived (split) and planed, or more often sawn by two men with a whipsaw, using saddleblocks to hold the log, and a saw pit for the pitman who worked below.

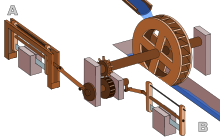

Early sawmills simply adapted the whipsaw to mechanical power, generally driven by a water wheel to speed up the process.

When the frame carrying the saw blade is in the topmost position it drops by its own weight, making a loud knocking noise, and in so doing it cuts the trunk.

Later the metal parts were obtained from the Netherlands,[6]: 94–95 where the technology was far ahead of that in England, where the sawmill remained largely unknown until the late 18th century.

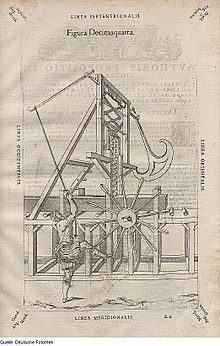

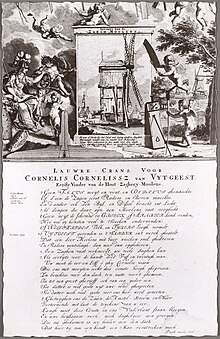

The Dutch windmill owner Cornelis Corneliszoon van Uitgeest invented in 1594 the wind-powered sawmill, which made the conversion of log timber into planks 30 times faster than before.

In the twentieth century the introduction of electricity and high technology furthered this process, and now most sawmills are massive and expensive facilities in which most aspects of the work is computerized.

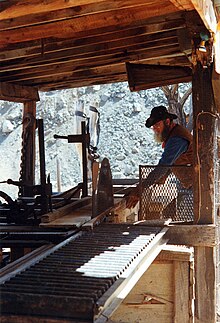

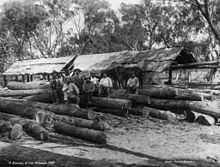

Small gasoline-powered sawmills run by local entrepreneurs served many communities in the early twentieth century, and specialty markets still today.