Masonry

However, the materials used, the quality of the mortar and workmanship, and the pattern in which the units are assembled can substantially affect the durability of the overall masonry construction.

Since mid-20th century, masonry has often featured steel-reinforced elements to help carry the tension force present in modern thin, light, tall building systems.

[1] Brick and concrete block are the most common types of masonry in use in industrialized nations and may be either load-bearing or non-load-bearing.

They generally provide great compressive strength and are best suited to structures with light transverse loading when the cores remain unfilled.

One problem with masonry walls is that they rely mainly on their weight to keep them in place; each block or brick is only loosely connected to the next via a thin layer of mortar.

The blocks sometimes have grooves or other surface features added to enhance this interlocking, and some dry set masonry structures forgo mortar altogether.

The wide selection of brick styles and types generally available in industrialized nations allow much variety in the appearance of the final product.

The attempts at rusticity of the late 20th century have been carried forward by masons specializing in a free, artistic style, where the courses are intentionally not straight, instead weaving to form more organic impressions.

They often are used as the structural core for veneered brick masonry or are used alone for the walls of factories, garages, and other industrial-style buildings where such appearance is acceptable or desirable.

Surface-bonding cement, which contains synthetic fibers for reinforcement, is sometimes used in this application and can impart extra strength to a block wall.

Typically, structures made of CMUs will have the top course of blocks in the walls filled with concrete and tied together with steel reinforcement to form a bond beam.

Another type of steel reinforcement referred to as ladder-reinforcement, can also be embedded in horizontal mortar joints of concrete block walls.

They can be split as part of the manufacturing process, giving the blocks a rough face replicating the appearance of natural stone, such as brownstone.

In most climates this insulation is much more effective on the exterior of the wall, allowing the building interior to take advantage of the aforementioned thermal mass of the masonry.

[citation needed] In addition to that, concrete masonry keeps fires contained to their room of origin 93% of the time.

[citation needed] For those reasons, concrete and masonry units hold the highest flame spread index classification, Class A.

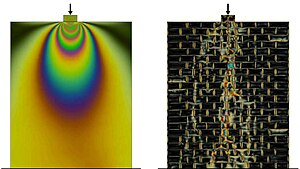

From the point of view of material modeling, masonry is a special material of extreme mechanical properties (with a very high ratio between strength in compression and in tension), so that the applied loads do not diffuse as they do in elastic bodies, but tend to percolate along lines of high stiffness.