Brickwork

[3] Brick is a popular medium for constructing buildings, and examples of brickwork are found through history as far back as the Bronze Age.

Much older examples of brickwork made with dried (but not fired) bricks may be found in such ancient locations as Jericho in Palestine, Çatal Höyük in Anatolia, and Mehrgarh in Pakistan.

The practice of laying uncut full-sized bricks wherever possible gives brickwork its maximum possible strength.

[18] Walls, running linearly and extending upwards, can be of varying depth or thickness.

Typically, the bricks are laid also running linearly and extending upwards, forming wythes or leafs.

Historically, the dominant method for consolidating the leaves together was to lay bricks across them, rather than running linearly.

This second course then resumes its paired run of stretcher and header, until the final pair is reached, whereupon a second and final queen closer is inserted as the penultimate brick, mirroring the arrangement at the beginning of the course, and duly closing the bond.

If the wall is arranged such that the bricks at the rear do not have this pattern, then the brickwork is said to be single Flemish bond.

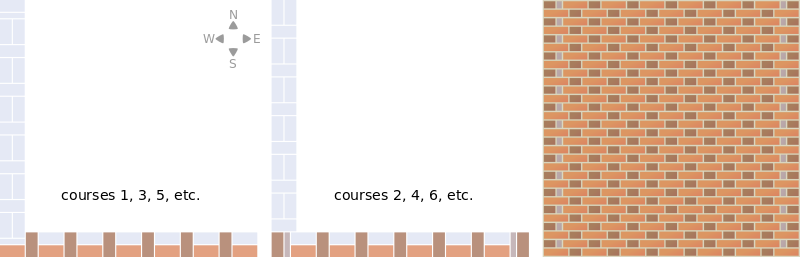

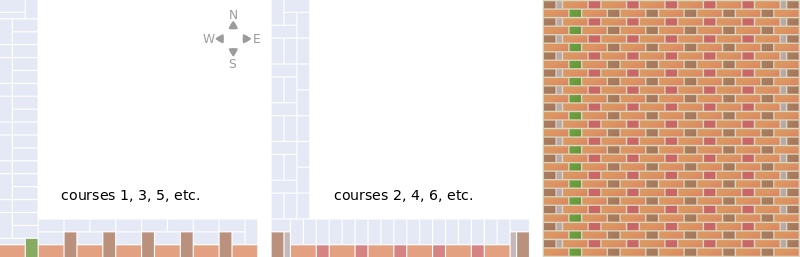

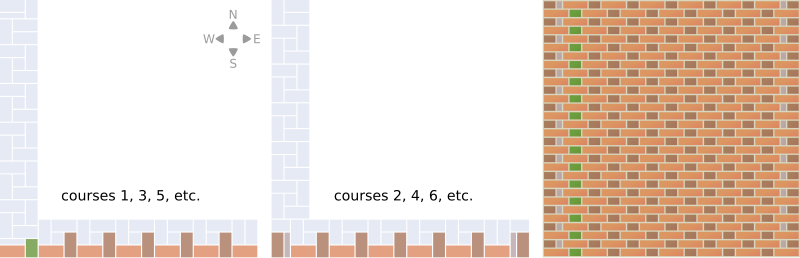

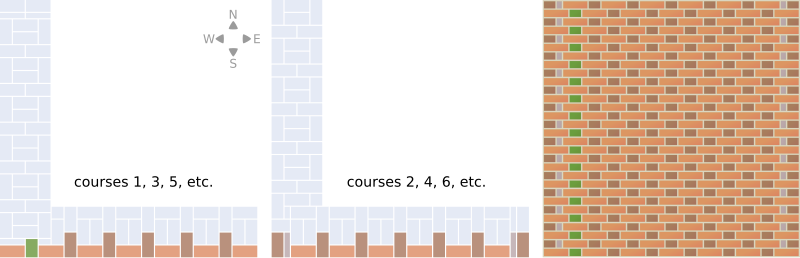

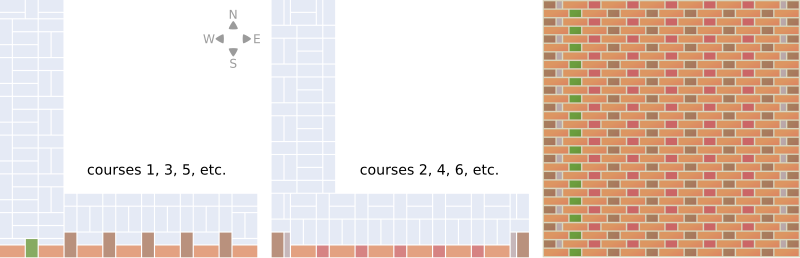

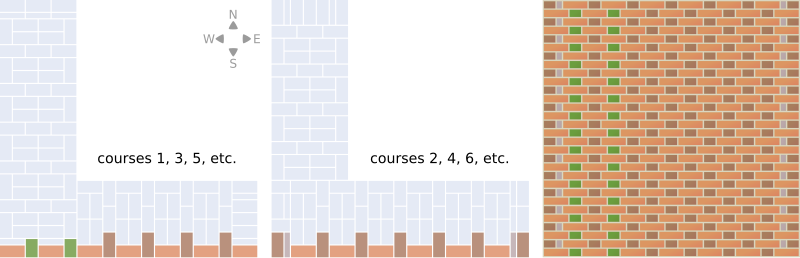

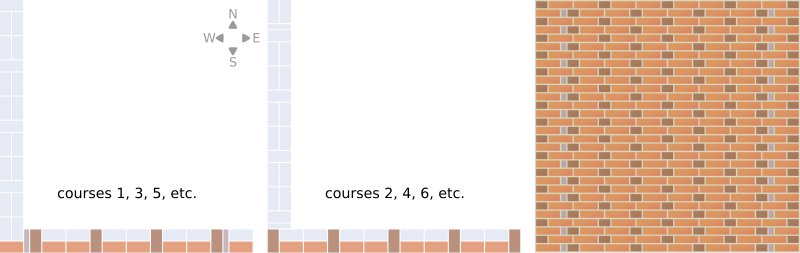

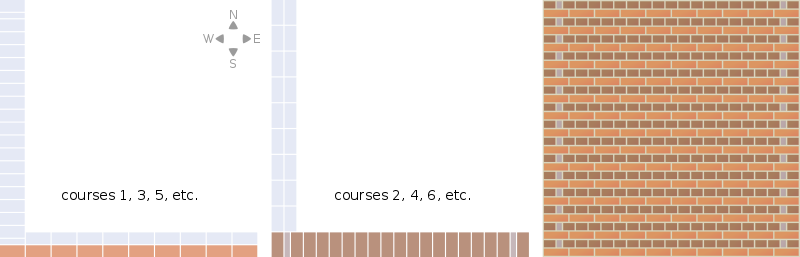

A lap (correct overlap) is generated by a queen closer on every alternate course: Double Flemish bond of one brick's thickness: overhead sections of alternate (odd and even) courses, and side elevation The colour-coded plans highlight facing bricks in the east–west wall.

These groups are laid next to each other for the length of a course, making brickwork one and a half bricks thick.

[34][35] To preserve the bond, it is necessary to lay a three-quarter bat instead of a header following a quoin stretcher at the corner of the wall.

[36] The great variety of monk bond patterns allow for many possible layouts at the quoins, and many possible arrangements for generating a lap.

The disposal of bricks in these often highly irregular raking patterns can be a challenging task for the bricklayer to correctly maintain while constructing a wall whose courses are partially obscured by scaffold, and interrupted by door or window openings, or other bond-disrupting obstacles.

If the bricklayer frequently stops to check that bricks are correctly arranged, then masonry in a raking monk bond can be expensive to build.

In spite of these complexities and their associated costs, the bond has proven a common choice for constructing brickwork in the north of Europe.

Raking courses in monk bond may—for instance—be staggered in such a way as to generate the appearance of diagonal lines of stretchers.

One method of achieving this effect relies on the use of a repeating sequence of courses with back-and-forth header staggering.

Such an example of a raking monk bond layout is shown in the New Malden Library, Kingston upon Thames, Greater London.

Elsewhere, raking courses in monk bond may be staggered in such a way as to generate a subtle appearance of indented pyramid-like diagonals.

[39] The bond's horizontally extended proportion suits long stretches of masonry such as garden walls or the run of brickwork over a ribbon window; conversely, the bond is less suitable for a surface occupied by many features, such as a Georgian façade.

[42][43] A muted colour scheme for occasional headers is sometimes used in English bond to lend a subtle texture to the brickwork.

In Dutch bond, all quoins are three-quarter bats—placed in alternately stretching and heading orientation with successive courses—and no use whatever is made of queen closers.

[50] For the standard English garden wall bond, headers are used as quoins for the middle stretching course in order to generate the lap, with queen closers as the penultimate brick at either end of the heading courses.

A more complex set of quoins and queen closers is necessary to achieve the lap for a raking English garden wall bond.

The heading course in English garden wall bond sometimes features bricks of a different colour to its surrounding stretchers.

In English chalk districts, flint is substituted for the stretchers, and the headers constitute a lacing course.

In Lewes, Sussex, England UK many small buildings are constructed in this bond, using blue coloured bricks and vitrified surfaces.

[57] A row of single basket weave bond comprises pairs of sailors laid side-by-side, capped with a shiner, alternating with pairs of sailors laid side-by-side sat atop a shiner.

[54] The herringbone pattern (opus spicatum) made by placing soldiers next to stretchers or vice versa (i.e. headers perpendicular) making 'L' shapes, nesting each L in the same order of laying.

This method of damp proofing appears as a distinctive navy blue band running around the circumference of a building.