Instrumentation

It is also a field of study about the art and science about making measurement instruments, involving the related areas of metrology, automation, and control theory.

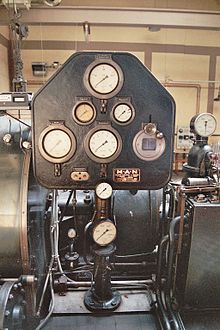

Instrumentation can refer to devices as simple as direct-reading thermometers, or as complex as multi-sensor components of industrial control systems.

Instruments can be found in laboratories, refineries, factories and vehicles, as well as in everyday household use (e.g., smoke detectors and thermostats).

Scales for comparing weights and simple pointers to indicate position are ancient technologies.

One of the oldest water clocks was found in the tomb of the ancient Egyptian pharaoh Amenhotep I, buried around 1500 BCE.

A drawing shows meteorological sensors moving pens over paper driven by clockwork.

[3] The concept has remained virtually unchanged as evidenced by pneumatic chart recorders, where a pressurized bellows displaces a pen.

Integrating sensors, displays, recorders, and controls was uncommon until the industrial revolution, limited by both need and practicality.

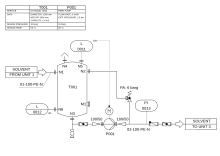

The ranges of pneumatic transmitters were defined by the need to control valves and actuators in the field.

Transistor electronics enabled wiring to replace pipes, initially with a range of 20 to 100mA at up to 90V for loop powered devices, reducing to 4 to 20mA at 12 to 24V in more modern systems.

[4] Instruments attached to a control system provided signals used to operate solenoids, valves, regulators, circuit breakers, relays and other devices.

The next logical development was the transmission of all plant measurements to a permanently staffed central control room.

Effectively this was the centralization of all the localized panels, with the advantages of lower manning levels and easy overview of the process.

It enabled sophisticated alarm handling, introduced automatic event logging, removed the need for physical records such as chart recorders, allowed the control racks to be networked and thereby located locally to plant to reduce cabling runs, and provided high level overviews of plant status and production levels.

Digital cameras and wristwatches might technically meet the loose definition of instrumentation because they record and/or display sensed information.

As the switch is rotated by the strip, the mercury makes physical (and thus electrical) contact between electrodes.

In addition to displays of engine rotational speed and vehicle linear speed, there are also displays of battery voltage and current, fluid levels, fluid temperatures, distance traveled, and feedback of various controls (turn signals, parking brake, headlights, transmission position).

[7] "Steam gauges" converted air pressures into needle deflections that could be interpreted as altitude and airspeed.

A modern aircraft has a far more sophisticated suite of sensors and displays, which are embedded into avionics systems.

They typically work for industries with automated processes, such as chemical or manufacturing plants, with the goal of improving system productivity, reliability, safety, optimization and stability.

Common concerns of both are the selection of appropriate sensors based on size, weight, cost, reliability, accuracy, longevity, environmental robustness, and frequency response.

In a research environment it is common for subject matter experts to have substantial instrumentation system expertise.

An astronomer knows the structure of the universe and a great deal about telescopes – optics, pointing and cameras (or other sensing elements).

For example, an astronomer is often knowledgeable of techniques to minimize temperature gradients that cause air turbulence within the telescope.