Mechanism (engineering)

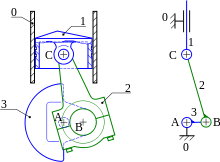

Mechanisms generally consist of moving components which may include Gears and gear trains; Belts and chain drives; cams and followers; Linkages; Friction devices, such as brakes or clutches; Structural components such as a frame, fasteners, bearings, springs, or lubricants; Various machine elements, such as splines, pins, or keys.

German scientist Franz Reuleaux defines machine as "a combination of resistant bodies so arranged that by their means the mechanical forces of nature can be compelled to do work accompanied by certain determinate motion".

From the time of Archimedes to the Renaissance, mechanisms were viewed as constructed from simple machines, such as the lever, pulley, screw, wheel and axle, wedge, and inclined plane.

Thus, the relative movement between points in two connected links is considered to result from the kinematic pair that joins them.

J. Phillips[clarification needed] shows that there are many ways to construct pairs that do not fit this simple model.

Similarly, the contact between the involute curves that form the meshing teeth of two gears are cam joints.

[1] An important consideration in this design process is the degree of freedom of the system of links and joints, which is determined using the Chebychev–Grübler–Kutzbach criterion.

An example of the three parameters that specify a spatial rotation are the roll, pitch and yaw angles used to define the orientation of an aircraft.

The rod ends let the input and output cranks of the RSSR linkage be misaligned to the point that they lie in different planes, which causes the coupler link to move in a general spatial movement.

The group SE(3)[clarification needed] is six-dimensional, which means the position of a body in space is defined by six parameters.

These mechanisms have many advantages, including reduced part-count, reduced "slop" between joints (no parasitic motion because of gaps between parts[3]), energy storage, low maintenance (they don't require lubrication and there is low mechanical wear), and ease of manufacture.

The transmission of rotation between contacting toothed wheels can be traced back to the Antikythera mechanism of Greece and the south-pointing chariot of China.

The implementation of the involute tooth yielded a standard gear design that provides a constant speed ratio.