Mechanical advantage

Machine components designed to manage forces and movement in this way are called mechanisms.

This means the ideal machine does not include a power source, is frictionless, and is constructed from rigid bodies that do not deflect or wear.

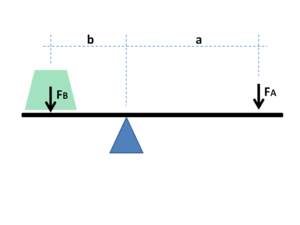

The lever is a movable bar that pivots on a fulcrum attached to or positioned on or across a fixed point.

The motion of the lever's end-point describes a fixed orbit, where mechanical energy can be exchanged.

In order to make use of non-collapsed mechanical advantage, it is necessary to use a 'true length' rotary lever.

The power input to a gear train with a torque TA applied to the drive pulley which rotates at an angular velocity of ωA is P=TAωA.

Because the power flow is constant, the torque TB and angular velocity ωB of the output gear must satisfy the relation which yields This shows that for an ideal mechanism the input-output speed ratio equals the mechanical advantage of the system.

The mechanical advantage of a pair of a chain drive or toothed belt drive with an input sprocket with NA teeth and the output sprocket has NB teeth is given by The mechanical advantage for friction belt drives is given by Chains and belts dissipate power through friction, stretch and wear, which means the power output is actually less than the power input, which means the mechanical advantage of the real system will be less than that calculated for an ideal mechanism.

Let S be the distance from the axle of the fixed block to the end of the rope, which is A where the input force is applied.

For an ideal block and tackle system there is no friction in the pulleys and no deflection or wear in the rope, which means the power input by the applied force FAVA must equal the power out acting on the load FBVB, that is The ratio of the output force to the input force is the mechanical advantage of an ideal gun tackle system, This analysis generalizes to an ideal block and tackle with a moving block supported by n rope sections, This shows that the force exerted by an ideal block and tackle is n times the input force, where n is the number of sections of rope that support the moving block.

Mechanical advantage that is computed using the assumption that no power is lost through deflection, friction and wear of a machine is the maximum performance that can be achieved.

The amount of this reduction from the ideal to the actual mechanical advantage (AMA) is defined by a factor called efficiency, a quantity which is determined by experimentation.

The second ratio also yields a MA of 6 in the ideal case but a smaller value in the practical scenario; it does not properly account for energy losses such as rope stretch.

The assumption of constant power thus allows use of the speed ratio to determine the maximum value for the mechanical advantage.

Actual mechanical advantage takes into account energy loss due to deflection, friction, and wear.