Mesoscale manufacturing

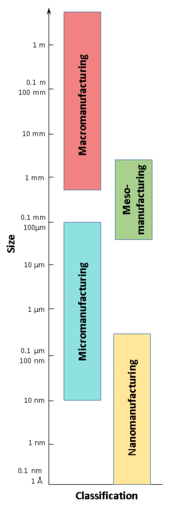

Mesoscale manufacturing is the process of creating components and products in a range of approximately from 0.1mm to 5mm with high accuracy and precision using a wide variety of engineering materials.

Specific applications include mechanical watches, and extremely small motors and bearings; lenses for cameras and other micro parts for mobile telephones; micro-batteries, mesoscale fuel cells, microscale pumps, valves, and mixing devices for microchemical reactors; biomedical implants, microholes for fiber optics; medical devices such as stents and valves; mini nozzles for high-temperature jets; mesoscale molds; desktop- or micro-factories, and many others.

[1] Laser machining is a traditional technique that uses nanosecond pulses of ultraviolet light to create mesoscale features like holes, fillets, etc.

The removal of material during laser machining is proportional to exposure time and therefore this process can be used to create three dimensional features.

This process involves focusing a beam of ions, for example gallium, to the work piece, causing material to be removed.