Ammeter

Instruments used to measure smaller currents, in the milliampere or microampere range, are designated as milliammeters or microammeters.

By the late 19th century, improved instruments were designed which could be mounted in any position and allowed accurate measurements in electric power systems.

The tangent galvanometer was used to measure currents using this effect, where the restoring force returning the pointer to the zero position was provided by the Earth's magnetic field.

The word makeup is similar to that of rheostat (also coined by Wheatstone) which was a device used to adjust the current in a circuit.

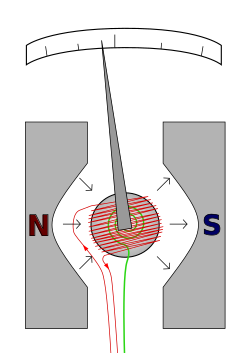

The modern form of this instrument was developed by Edward Weston, and uses two spiral springs to provide the restoring force.

The uniform air gap between the iron core and the permanent magnet poles make the deflection of the meter linearly proportional to current.

A DC ammeter is thus sensitive to which polarity it is connected in; most are marked with a positive terminal, but some have centre-zero mechanisms[a] and can display currents in either direction.

Indeed, some Ammeters of this type do not have hairsprings at all, instead using a fixed permanent magnet to provide the restoring force.

Moving iron ammeters are commonly used to measure current in industrial frequency AC circuits.

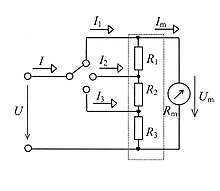

Digital ammeter designs use a shunt resistor to produce a calibrated voltage proportional to the current flowing.

Other modern picoammeters use log compression and a "current sink" method that eliminates range switching and associated voltage spikes.

The use of a shunt or current transformer also allows convenient location of the indicating meter without the need to run heavy circuit conductors up to the point of observation.

Ammeters must not be connected directly across a voltage source since their internal resistance is very low and excess current would flow.

Ordinary Weston-type meter movements can measure only milliamperes at most, because the springs and practical coils can carry only limited currents.

Zero-center ammeters are used for applications requiring current to be measured with both polarities, common in scientific and industrial equipment.

In a similar way, accurate AC/DC non-contact ammeters have been constructed using Hall effect magnetic field sensors.

A portable hand-held clamp-on ammeter is a common tool for maintenance of industrial and commercial electrical equipment, which is temporarily clipped over a wire to measure current.

Some recent types have a parallel pair of magnetically soft probes that are placed on either side of the conductor.

Spring providing restoring force

This illustration is conceptual; in a practical meter, the iron core is stationary, and front and rear spiral springs carry current to the coil, which is supported on a rectangular bobbin. Furthermore, the poles of the permanent magnet are arcs of a circle.