Molecular sieve

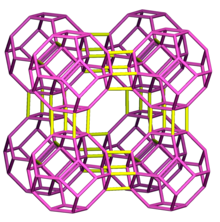

A molecular sieve is a material with pores (voids or holes), having uniform size comparable to that of individual molecules, linking the interior of the solid to its exterior.

Zeolites are almost always aluminosilicates, or variants where some or all of the Si or Al centers are replaced by similarly charged elements.

As a mixture of molecules migrates through the stationary bed of porous, semi-solid substance referred to as a sieve (or matrix), the components of the highest molecular weight (which are unable to pass into the molecular pores) leave the bed first, followed by successively smaller molecules.

Most of molecular sieves are aluminosilicates (zeolites) with Si/Al molar ratio less than 2, but there are also examples of activated charcoal and silica gel.

They catalyze isomerisation, alkylation, and epoxidation, and are used in large scale industrial processes, including hydrocracking and fluid catalytic cracking.

[10] Prior to this approval the European Union had used molecular sieves with pharmaceuticals and independent testing suggested that molecular sieves meet all government requirements but the industry had been unwilling to fund the expensive testing required for government approval.

3A molecular sieves are used to dry a range of materials, such as ethanol, air, refrigerants, natural gas and unsaturated hydrocarbons.

Some molecular sieves are used to assist detergents as they can produce demineralized water through calcium ion exchange, remove and prevent the deposition of dirt.

Spherical beads have advantage over other shapes as they offer lower pressure drop and are mechanically robust.