Mullard

The head office in later years was Mullard House at 1–19 Torrington Place, Bloomsbury, now part of University College London.

The valves (vacuum tubes) produced in this period were named with the prefix PM, for Philips-Mullard, beginning with the PM3 and PM4 in 1926.

Both buildings had a very distinctive flat roof construction and were very similar to those at Philips' headquarters in Eindhoven, Netherlands.

The plant was planned to be the biggest semiconductor facility in Europe, employing 3,000 people including 200 scientists and engineers.

In 1962 Associated Semiconductor Manufacturers (ASM) Ltd was formed by Mullard and GEC to combine the semiconductor development and production facilities of the two companies; Mullard owned two-thirds of the company and included the Southampton plant; GEC contributed their small factory in School Street, Hazel Grove, producing thyristors, rectifiers and power diodes.

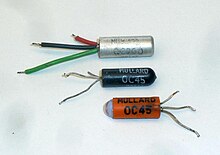

Mullard's first silicon transistors were the OC201 to OC207, PNP alloy types using the standard SO-2 metal-over-glass construction such as the OC200 shown.

From about 1960 Mullard switched to using the BC prefix for silicon, and AC for germanium, eliminating the confusion of part numbers.

In 1964 the company produced a prototype electronic desktop calculator as a technology demonstrator for its transistors and cold cathode indicator tubes.

In 1957 Philips-Mullard helped to set up the Mullard Radio Astronomy Observatory (MRAO) at the University of Cambridge.

In 1966 the Mullard Space Science Laboratory (MSSL) was opened near Dorking, Surrey as part of University College London.

The Royal Society Mullard Award for "those who have an outstanding academic record in any area of natural science, engineering or technology and to individuals or teams whose work has the potential to make a contribution to national prosperity", previously for young researchers[11] but as of 2025[update] with no restrictions on career stage, has been awarded annually from 1967.

Mullard's quest was simple, they wanted a world-beater, nothing less, so they contacted the renowned grower Sam McGredy IV in Northern Ireland.

- OC200, silicon PNP transistor in an aluminium can.

- Germanium OC45 in a black-painted glass package.

- OC45 in a clear glass and blue putty package, with rubber sleeve