Nanofiber

Examples of natural polymers include collagen, cellulose, silk fibroin, keratin, gelatin and polysaccharides such as chitosan and alginate.

[5] All polymer nanofibers are unique for their large surface area-to-volume ratio, high porosity, appreciable mechanical strength, and flexibility in functionalization compared to their microfiber counterparts.

[1][2][6] There exist many different methods to make nanofibers, including drawing, electrospinning, self-assembly, template synthesis, and thermal-induced phase separation.

[28][29] Beginning with the development of the electrospinning method, English physicist William Gilbert (1544-1603) first documented the electrostatic attraction between liquids by preparing an experiment in which he observed a spherical water drop on a dry surface warp into a cone shape when it was held below an electrically charged amber.

[29] In 1966, Harold Simons published a patent for a device that could produce thin and light nanofiber fabrics with diverse motifs.

[36][6] [37][38][39][40] The instruments necessary for electrospinning include a high voltage supplier, a capillary tube with a pipette or needle with a small diameter, and a metal collecting screen.

As the intensity of the electric field increases, the hemispherical surface of the fluid at the tip of the capillary tube elongates to form a conical shape known as the Taylor cone.

A critical value is attained upon further increase in the electric field in which the repulsive electrostatic force overcomes the surface tension and the charged jet of fluid is ejected from the tip of the Taylor cone.

Nanofibers can also be collected in a highly aligned fashion by using specialized collectors such as the rotating drum,[42] metal frame,[43] or a two-parallel plates system.

[44] Parameters such as jet stream movement and polymer concentration have to be controlled to produce nanofibers with uniform diameters and morphologies.

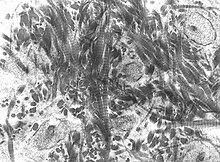

[6][46][47] This resemblance is a major advantage of electrospinning because it opens up the possibility of mimicking the ECM with regards to fiber diameters, high porosity, and mechanical properties.

A limitation, however, is that only a viscoelastic material that can undergo extensive deformations while possessing sufficient cohesion to survive the stresses developed during pulling can be made into nanofibers through this process.

[51][52] This method can be used to prepare fibrils and tubules of many types of materials, including metals, semiconductors and electronically conductive polymers.

The method was inspired by the natural folding process of amino acid residues to form proteins with unique three-dimensional structures.

[54] Due to their high porosity and large surface area-to-volume ratio, nanofibers are widely used to construct scaffolds for biological applications.

[1][2] Major examples of natural polymers used in scaffold production are collagen, cellulose, silk fibroin, keratin, gelatin and polysaccharides such as chitosan and alginate.

PCL can be combined with other materials such as gelatin, collagen, chitosan, and calcium phosphate to improve the differentiation and proliferation capacity (2, 17).

[58] A blend of PLLA and PLGA scaffold matrix has shown proper biomimetic structure, good mechanical strength and favorable bioactivity.

[1][2] Simon, in a 1988 NIH SBIR grant report, showed that electrospinning could be used to produce nano- and submicron-scale polystyrene and polycarbonate fibrous mats specifically intended for use as in vitro cell substrates.

[7] The bone tissue is arranged either in a compact or trabecular pattern and composed of organized structures that vary in length from the centimeter range all the way to the nanometer scale.

[9][10][70] Natural polymers such as gelatin and alginate make for good fabrication biomaterials for carrier nanofibers because of their biocompatibility and biodegradability that result in no harm to the tissue of the host and no toxic accumulation in the human body, respectively.

As a result, the fibers possess high drug-loading capacity and may release therapeutic molecules over a large surface area.

It has been found that the number of CTCs present in the bloodstream of patients with metastatic prostate and colorectal cancer is prognostic of the overall survival of tumors.

[17] Also the large volume changes resulting from continuous conversion of oxygen between its gaseous and solid state puts stress on the electrode and limits its lifetime.

[83] Zhu et al. developed a novel cathode that can store lithium and oxygen in the electrode they named nanolithia which is a matrix of carbon nanofibers periodically embedded with cobalt oxide.

Wang et al. successfully developed nanofibrous thin film optical sensors for metal ion (Fe3+ and Hg2+) and 2,4-dinitrotoluene (DNT) detection using the electrospinning technique.

[87] Kelly et al. developed a sensor that warns first responders when the carbon filters in their respirators have become saturated with toxic fume particles.

In order to easily determine when the filter is spent, Kelly and his team developed a mask equipped with a sensor composed of carbon nanofibers assembled into repeating structures called photonic crystals that reflect specific wavelengths of light.

Scholten et al. showed that adsorption and desorption of VOC by electrospun nanofibrous membrane were faster than the rates of conventional activated carbon.

This extremely dense "sieve" with more than 2,5 billion of pores per square centimeter works much more efficiently with vapor removal and brings better level of water resistance.