Niobium capacitor

Reverse voltages or ripple currents higher than specified tolerances can destroy the dielectric and thus the capacitor; the resulting short circuit can cause a fire or explosion in larger units.

Niobium oxide is a hard ceramic material characterized by high metallic conductivity.

With the collapse of the Iron Curtain, the technology became better-known in the West, with major capacitor manufacturers taking interest in the late 1990s.

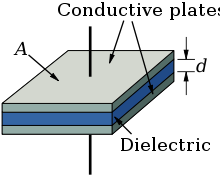

The dielectric thickness of niobium electrolytic capacitors is very thin, in the range of nanometers per volt.

In such a comparison the values for ESR and ripple current load are the most important parameters for the use of electrolytic capacitors in modern electronic equipment.

The lower the ESR the higher the ripple current per volume, thus the better the functionality of the capacitor in the circuit.

(1) 100 μF/10 V, unless otherwise specified, (2) calculated for a capacitor 100 μF/10 V, The phenomenon that can electrochemically form an oxide layer on aluminum and metals like tantalum or niobium, blocking an electric current in one direction but allowing it to flow in the other direction, was discovered in 1875 by the French researcher Eugène Ducretet.

The solution found by R. L. Taylor and H. E. Haring of the Bell Labs was based on experience with ceramics.

[13][14] These first sintered tantalum capacitors used a non-solid electrolyte not consistent with the concept of solid state electronics.

All properties can be defined and specified by a series equivalent circuit composed out of an idealized capacitance and additional electrical components which model all losses and inductive parameters of a capacitor.

For abbreviated marking in tight spaces, a letter code for each tolerance is specified in IEC 60062.

Lower voltage applied may have positive influences for tantalum (and niobium) electrolytic capacitors.

Lowering the voltage applied increases the reliability and reduces the expected failure rate.

General information to impedance, ESR, dissipation factor tan δ, ripple current, and leakage current see electrolytic capacitor For general information on reliability and failure rate see electrolytic capacitor.

[18][19][20] The different types of electrolytic capacitors show different behaviors in long-term stability, inherent failure modes and their self-healing mechanisms.

Application rules for types with an inherent failure mode are specified to ensure capacitors high reliability and long life.

A rare failure in solid electrolytic capacitors is breakdown of the dielectric caused by faults or impurities.

As more energy is applied to a faulty solid niobium eventually either the high ohmic NbO2 channel or the Nb2O5 dielectric breaks down and the capacitor exhibits a thermal runaway failure.

This gives a significant reduction (95%) of the ignition failure mode compared to solid tantalum capacitors.

If the failure is a short circuit (the most common occurrence), and current is not limited to a safe value, catastrophic thermal runaway may occur.

For electronics manufacturers in the United States the EIA publish a standard for niobium and tantalum chip capacitors: