Nuclear meltdown

A core damage incident can occur even after a reactor is shut down because the fuel continues to produce decay heat.

Many commercial reactors are contained within a 1.2-to-2.4-metre (3.9 to 7.9 ft) thick pre-stressed, steel-reinforced, air-tight concrete structure that can withstand hurricane-force winds and severe earthquakes.

[7] If such a limiting fault occurs, and a complete failure of all ECCS divisions also occurs, both Kuan, et al and Haskin, et al describe six stages between the start of the limiting fault (the loss of cooling) and the potential escape of molten corium into the containment (a so-called "full meltdown"):[8][9] At the point at which the corium relocates to the lower plenum, Haskin, et al relate that the possibility exists for an incident called a fuel–coolant interaction (FCI) to substantially stress or breach the primary pressure boundary when the corium relocates to the lower plenum of the reactor pressure vessel ("RPV").

In the event of lower plenum failure, debris at varied temperatures can be expected to be projected into the cavity below the core.

This was due to outgassing by an uncontrolled system that, today, would have been backfitted with activated carbon and HEPA filters to prevent radionuclide release.

[14][15] As the natural decay heat of the corium eventually reduces to an equilibrium with convection and conduction to the containment walls, it becomes cool enough for water spray systems to be shut down and the reactor to be put into safe storage.

Another scenario sees a buildup of potentially explosive hydrogen, but passive autocatalytic recombiners inside the containment are designed to prevent this.

There were initial concerns that the hydrogen might ignite and damage the pressure vessel or even the containment building; but it was soon realized that lack of oxygen prevented burning or explosion.

[16] One scenario consists of the reactor pressure vessel failing all at once, with the entire mass of corium dropping into a pool of water (for example, coolant or moderator) and causing extremely rapid generation of steam.

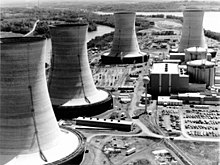

The Three Mile Island accident provided real-life experience with a molten core: the corium failed to melt through the reactor pressure vessel after over six hours of exposure due to dilution of the melt by the control rods and other reactor internals, validating the emphasis on defense in depth against core damage incidents.

The first is the bulk heavy-water moderator (a separate system from the coolant), and the second is the light-water-filled shield tank (or calandria vault).

[21] Other failure modes aside from fuel melt will probably occur in a CANDU rather than a meltdown, such as deformation of the calandria into a non-critical configuration.

Soviet-designed RBMK reactors (Reaktor Bolshoy Moshchnosti Kanalnyy), found only in Russia and other post-Soviet states and now shut down everywhere except Russia, do not have containment buildings, are naturally unstable (tending to dangerous power fluctuations), and have emergency cooling systems (ECCS) considered grossly inadequate by Western safety standards.

Xenon-135, a neutron absorbent fission product, has a tendency to build up in the core and burn off unpredictably in the event of low power operation.

Training has been provided in safety assessment from Western sources, and Russian reactors have evolved in response to the weaknesses that were in the RBMK.

Upon entering the EU in 2004, Lithuania was required to phase out its two RBMKs at Ignalina NPP, deemed incompatible with European nuclear safety standards.

The MKER is a modern Russian-engineered channel type reactor that is a distant descendant of the RBMK, designed to optimize the benefits and fix the serious flaws of the original.

An array of improvements make the MKER's safety comparable to Western Generation III reactors: improved quality of parts, advanced computer controls, comprehensive passive emergency core cooling system, and very strong containment structure, along with a negative void coefficient and a fast-acting rapid shutdown system.

This is because it uses light water as a moderator (rather than graphite), has well-understood operating characteristics, and has a negative void coefficient of reactivity.

In addition, some have been built with more than marginal containments, some have quality ECCS systems, and some have been upgraded to international standards of control and instrumentation.

One point of distinction in which the VVER surpasses the West is the reactor water cleanup facility—built, no doubt, to deal with the enormous volume of rust within the primary coolant loop—the product of the slow corrosion of the RPV.

Though confinements cannot be transformed into containments, the risk of a limiting fault resulting in core damage can be greatly reduced.

In addition, passive safety features such as 900-tonne ice condensers have been installed, making these two units safety-wise the most advanced VVER-440s in the world.

The CANDU reactor has two low-temperature and low-pressure water systems surrounding the fuel (i.e. moderator and shield tank) that act as back-up heat sinks and preclude meltdowns and core-breaching scenarios.

This was well below the boiling point of the unpressurised liquid metal coolant, which had entirely sufficient cooling ability to deal with the heat of fission product radioactivity, by simple convection.

The second test, deliberate shut-off of the secondary coolant loop that supplies the generators, caused the primary circuit to undergo the same safe shutdown.

The China syndrome (loss-of-coolant accident) is a nuclear reactor operations accident characterized by the severe meltdown of the core components of the reactor, which then burn through the containment vessel and the housing building, then (figuratively) through the crust and body of the Earth until reaching the opposite end, presumed to be in "China".

[citation needed] The system design of the nuclear power plants built in the late 1960s raised the concern that a severe reactor accident could release large quantities of radioactive materials into the atmosphere and environment.

The number of people killed would depend on which way the wind was blowing, rendering an area the size of Pennsylvania permanently uninhabitable."

There was concern that a steam explosion would have occurred if the hot corium made contact with the water, resulting in more radioactive materials being released into the air.

- Inlet 2B

- Inlet 1A

- Cavity

- Loose core debris

- Crust

- Previously molten material

- Lower plenum debris

- Possible region depleted in uranium

- Ablated incore instrument guide

- Hole in baffle plate

- Coating of previously molten material on bypass region interior surfaces

- Upper grid damage