Operations management

Operations management is concerned with designing and controlling the production of goods and services,[1] ensuring that businesses are efficient in using resources to meet customer requirements.

[2] Operations management covers sectors like banking systems, hospitals, companies, working with suppliers, customers, and using technology.

Each of these requires an ability to analyze the current situation and find better solutions to improve the effectiveness and efficiency of manufacturing or service operations.

The next major historical application of operation systems occurred in 4000 B.C., when the Egyptians started using planning, organization, and control in large projects such as the construction of the pyramids.

Although guilds were regulated as to the quality of work performed, the resulting system was rather rigid, shoemakers, for example, were prohibited from tanning hides.

[citation needed] In 1883, Frederick Winslow Taylor introduced the stopwatch method for accurately measuring the time to perform each single task of a complicated job.

He developed the scientific study of productivity and identifying how to coordinate different tasks to eliminate wasting of time and increase the quality of work.

The next generation of scientific study occurred with the development of work sampling and predetermined motion time systems (PMTS).

PMTS allows the use of standard predetermined tables of the smallest body movements (e.g. turning the left wrist by 90°), and integrating them to predict the time needed to perform a simple task.

[10] The idea of the production line has been used multiple times in history prior to Henry Ford: the Venetian Arsenal (1104); Smith's pin manufacturing, in the Wealth of Nations (1776) or Brunel's Portsmouth Block Mills (1802).

During World War II, the growth of computing power led to further development of efficient manufacturing methods and the use of advanced mathematical and statistical tools.

The synergy of operations research and systems engineering allowed for the realization of solving large scale and complex problems in the modern era.

In 1851 at the Crystal Palace Exhibition the term American system of manufacturing was used to describe the new approach that was evolving in the United States of America which was based on two central features: interchangeable parts and extensive use of mechanization to produce them.

Since all sectors are highly interconnected, this did not reflect less importance for manufacturing, agriculture, and mining but just a shift in the type of economic activity.

Although productivity benefited considerably from technological inventions and division of labor, the problem of systematic measurement of performances and the calculation of these by the use of formulas remained somewhat unexplored until Frederick Taylor, whose early work focused on developing what he called a "differential piece-rate system"[13] and a series of experiments, measurements and formulas dealing with cutting metals[14] and manual labor.

In 1913 Ford Whitman Harris published a paper on "How many parts to make at once", in which he presented the idea of the economic order quantity model.

He described the problem as follows: "Interest on capital tied up in wages, material and overhead sets a maximum limit to the quantity of parts which can be profitably manufactured at one time; "setup costs" on the job fix the minimum.

[18] His paper inspired a large body of mathematical literature focusing on the problem of production planning and inventory control.

[citation needed] In 1924 Walter Shewhart introduced the control chart through a technical memorandum while working at Bell Labs, central to his method was the distinction between common cause and special cause of variation.

Toyota evolved a unique manufacturing system centered on two complementary notions: just in time (produce only what is needed) and autonomation (automation with a human touch).

This period also marks the spread of total quality management (TQM) in Japan, ideas initially developed by American authors such as Deming, Juran and Armand V.

[31] Walmart provided the first example of very low cost retailing through design of their stores and efficient management of their entire supply chain.

The operations system included careful selection of merchandise, low cost sourcing, ownership of transportation, cross-docking, efficient location of stores and friendly home-town service to the customer.

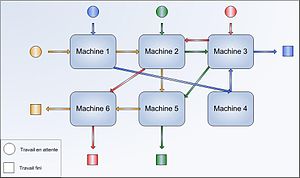

Recent trends in the field revolve around concepts such as: A production system comprises both technological elements (machines and tools) and organizational behavior (division of labor and information flow) needed to produce goods and services.

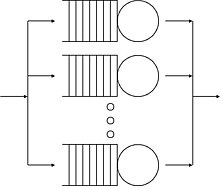

Although estimating throughput for a single process maybe fairly simple, doing so for an entire production system involves an additional difficulty due to the presence of queues which can come from: machine breakdowns, processing time variability, scraps, setups, maintenance time, lack of orders, lack of materials, strikes, bad coordination between resources, mix variability, plus all these inefficiencies tend to compound depending on the nature of the production system.

Overall equipment effectiveness (OEE) is defined as the product between system availability, cycle time efficiency and quality rate.

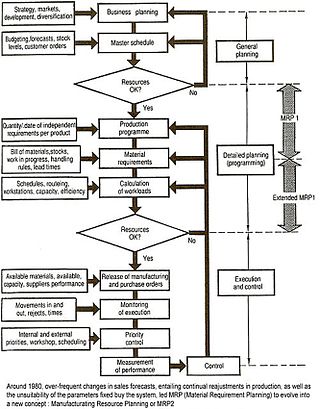

The traditional pull approach to inventory control, a number of techniques have been developed based on the work of Ford W. Harris[18] (1913), which came to be known as the economic order quantity (EOQ) model.

It comes mainly from the ideas of Taiichi Ohno and Toyoda Sakichi which are centered on the complementary notions of just in time and autonomation (jidoka), all aimed at reducing waste (usually applied in PDCA style).

Some additional elements are also fundamental:[49] production smoothing (Heijunka), capacity buffers, setup reduction, cross-training and plant layout.

[52] Computations of safety stocks are usually based on modeling demand as a normal distribution and MRP and some inventory problems can be formulated using optimal control.