Polypropylene

Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951.

[3] This pioneering discovery led to large-scale commercial production of isotactic polypropylene by the Italian firm Montecatini from 1957 onwards.

This arrangement creates a greater degree of crystallinity and results in a stiffer material that is more resistant to creep than both atactic polypropylene and polyethylene.

[9] Propylene molecules prefer to join together "head-to-tail", giving a chain with methyl groups on every other carbon, but some randomness occurs.

Due to the tertiary carbon atom, PP is chemically less resistant than PE (see Markovnikov rule).

Polypropylene with higher MFR will fill the plastic mold more easily during the injection or blow-molding production process.

Ethylene-propylene rubber or EPDM added to polypropylene homopolymer increases its low temperature impact strength.

As the methyl group is in isotactic propylene consistently located at the same side, it forces the macromolecule in a helical shape, as also found in starch.

The higher the isotonicity(the isotactic fraction), the greater the crystallinity, and thus also the softening point, rigidity, e-modulus and hardness.

[6]: 22 Atactic polypropylene, on the other hand, lacks any regularity, which prevents it from crystallization, thereby creating an amorphous material.

The mesomorphic phase is considered as cause for the transparency in rapidly cooled films (due to low order and small crystallites).

Due to its lack of crystallinity, it is readily soluble even at moderate temperatures, which allows to separate it as by-product from isotactic polypropylene by extraction.

[1] Microbial communities isolated from soil samples mixed with starch have been shown to be capable of degrading polypropylene.

These catalysts are activated with special co-catalysts containing an organoaluminium compound such as Al(C2H5)3 and the second type of a modifier.

The large number of end-use applications for polypropylene are often possible because of the ability to tailor grades with specific molecular properties and additives during its manufacture.

Surface treatments can be applied to polypropylene parts in order to promote adhesion of printing ink and paints.

It was observed that PP can be expanded to make EPP through controlling its crystalline structure or through blending with other polymers.

Polypropylene is used in the manufacturing of piping systems, both ones concerned with high purity and ones designed for strength and rigidity (e.g., those intended for use in potable plumbing, hydronic heating and cooling, and reclaimed water).

[42] This material is often chosen for its resistance to corrosion and chemical leaching, its resilience against most forms of physical damage, including impact and freezing, its environmental benefits, and its ability to be joined by heat fusion rather than gluing.

For this reason, most plastic tubs for dairy products are polypropylene sealed with aluminum foil (both heat-resistant materials).

Such containers provide a good hands-on example of the difference in modulus, since the rubbery (softer, more flexible) feeling of LDPE with respect to polypropylene of the same thickness is readily apparent.

Plastic pails, car batteries, wastebaskets, pharmacy prescription bottles, cooler containers, dishes and pitchers are often made of polypropylene or HDPE, both of which commonly have rather similar appearance, feel, and properties at ambient temperature.

When polypropylene is biaxially oriented, it becomes crystal clear and serves as an excellent packaging material for artistic and retail products.

The wide color range, durability, low cost, and resistance to dirt make it ideal as a protective cover for papers and other materials.

[51] Although polypropylene clothes are not easily flammable, they can melt, which may result in severe burns if the wearer is involved in an explosion or fire of any kind.

A small patch of the material is placed over the spot of the hernia, below the skin, and is painless and rarely, if ever, rejected by the body.

[54] Due to the above-mentioned propensity for polypropylene mesh to erode the tissue surrounding it, the FDA has issued several warnings on the use of polypropylene mesh medical kits for certain applications in pelvic organ prolapse, specifically when introduced in close proximity to the vaginal wall due to a continued increase in number of mesh-driven tissue erosions reported by patients over the past few years.

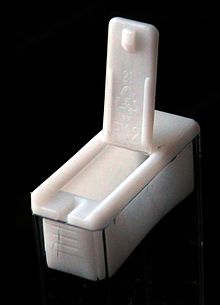

[57] Polypropylene has the number "5" as its resin identification code:[58] PP objects can be joined with a two-part epoxy glue or using hot-glue guns.

With polypropylene, the melted welding rod must be "mixed" with the semi-melted base material being fabricated or repaired.

[61] Polypropylene was the most common microplastic fiber found in the olfactory bulbs in 8 of 15 deceased individuals in a study.