Porosity

Porosity is a fraction between 0 and 1, typically ranging from less than 0.005 for solid granite to more than 0.5 for peat and clay.

The porosity of a rock, or sedimentary layer, is an important consideration when attempting to evaluate the potential volume of water or hydrocarbons it may contain.

Sedimentary porosity is a complicated function of many factors, including but not limited to: rate of burial, depth of burial, the nature of the connate fluids, the nature of overlying sediments (which may impede fluid expulsion).

One commonly used relationship between porosity and depth is the decreasing exponential function given by the Athy (1930) equation:[3] where,

: If the void space is filled with air, the following simpler form may be used: A mean normal particle density can be taken as approximately 2.65 g/cm3 (silica, siliceous sediments or aggregates), or 2.70 g/cm3 (calcite, carbonate sediments or aggregates), although a better estimation can be obtained by examining the lithology of the particles.

Porosity can be proportional to hydraulic conductivity; for two similar sandy aquifers, the one with a higher porosity will typically have a higher hydraulic conductivity (more open area for the flow of water), but there are many complications to this relationship.

For example: clays typically have very low hydraulic conductivity (due to their small pore throat radii) but also have very high porosities (due to the structured nature of clay minerals), which means clays can hold a large volume of water per volume of bulk material, but they do not release water rapidly and therefore have low hydraulic conductivity.

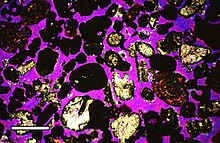

The graphic illustrates how some smaller grains can effectively fill the pores (where all water flow takes place), drastically reducing porosity and hydraulic conductivity, while only being a small fraction of the total volume of the material.

For tables of common porosity values for earth materials, see the "further reading" section in the Hydrogeology article.

Consolidated rocks (e.g., sandstone, shale, granite or limestone) potentially have more complex "dual" porosities, as compared with alluvial sediment.

Connected porosity is more easily measured through the volume of gas or liquid that can flow into the rock, whereas fluids cannot access unconnected pores.

Porosity is controlled by: rock type, pore distribution, cementation, diagenetic history and composition.

Porosity of surface soil typically decreases as particle size increases.

Heavy apparently refers to a gravitational moisture content effect in combination with terminology that harkens back to the relative force required to pull a tillage implement through the clayey soil at field moisture content as compared to sand.

Porosity of 0.20 is considered normal for unsorted gravel size material at depths below the biomantle.

Porosity in finer material below the aggregating influence of pedogenesis can be expected to approximate this value.

While porosity is inherent in die casting manufacturing, its presence may lead to component failure where pressure integrity is a critical characteristic.

The end result of porosity is the creation of a leak path through the walls of a casting that prevents the part from holding pressure.

Porosity may also lead to out-gassing during the painting process, leaching of plating acids and tool chatter in machining pressed metal components.