Powder-actuated tool

They can more easily be used in narrow or awkward locations, such as installing steel suspension clips into an overhead concrete ceiling.

[1] High-velocity tools made or sold in the United States must comply under certain circumstances;[2] with many being used in the shipbuilding and steel industries.

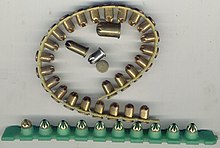

Powder-actuated fasteners are made of special heat-treated steel; common nails are unsafe for this application.

Powder-actuated technology was developed for commercial use during the Second World War, when high-velocity fastening systems were used to temporarily repair damage to ships.

The three single-shot strengths or colors typically sold to the general public are brown, green, and yellow in brass-colored casings.

This helps ensure that the gun does not discharge in an unsafe manner, causing the nail to become an unrestrained projectile.

[6] Most manufacturers of powder-actuated nail guns offer training and certification, some with no further charge online testing.