Power-to-gas

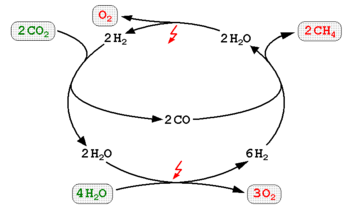

[4] Single-stage P2G systems to produce methane also exist, such as reversible solid oxide cell (rSOC) technology.

[2] ITM Power won a tender in March 2013 for a Thüga Group project, to supply a 360 kW self-pressurising high-pressure electrolysis rapid response proton exchange membrane (PEM) electrolyser Rapid Response Electrolysis Power-to-Gas energy storage plant.

The operational data will be shared by the whole Thüga group – the largest network of energy companies in Germany with around 100 municipal utility members.

An expansion of the pilot plant is planned from 2016, facilitating the full conversion of the hydrogen produced into methane to be directly injected into the natural gas grid.

[22] In France, the MINERVE demonstrator of AFUL Chantrerie (Federation of Local Utilities Association) aims to promote the development of energy solutions for the future with elected representatives, companies and more generally civil society.

[23] A full scale 1GW electrolyzer operated by EWE and Tree Energy Solutions is planned at the gas terminal in Wilhelmshaven, Germany.

The produced synthetic natural gas, named Audi e-gas, enables CO2-neutral mobility with standard CNG vehicles.

[31] In April 2014 the European Union's co-financed and from the KIT coordinated[32] HELMETH[33] (Integrated High-Temperature ELectrolysis and METHanation for Effective Power to Gas Conversion) research project started.

The SOEC works with a pressure of up to 15 bar, steam conversions of up to 90% and generates one standard cubic meter of hydrogen from 3.37 kWh of electricity as feed for the methanation.

The technological maturity of Power to Gas is evaluated in the European 27 partner project STORE&GO, which has started in March 2016 with a runtime of four years.

The overall goal of the project is to assess those technologies and various usage paths under technical,[39] economic,[40] and legal [41] aspects to identify business cases on the short and on the long term.

[44][45] This microbial power-to-gas reaction occurs at ambient conditions, i.e. room temperature and pH 7, at efficiencies that routinely reach 80-100%.

[52] Methane can be used to produce LPG by synthesising SNG with partial reverse hydrogenation at high pressure and low temperature.

LPG in turn can be converted into alkylate which is a premium gasoline blending stock because it has exceptional antiknock properties and gives clean burning.

[53][54][55][need quotation to verify]The carbon dioxide gas produced as by-product from these plants can be recycled in the generation of synthetic methane (SNG).

Similarly, oxygen gas produced as by product from the electrolysis of water and the methanation process can be consumed in the cultivation of bacteria culture.

With these integrated plants, the abundant renewable solar and wind power potential can be converted into high value food products without any water pollution or greenhouse gas (GHG) emissions.

The impurities carbon dioxide, water, hydrogen sulfide, and particulates must be removed from the biogas if the gas is used for pipeline storage to prevent damage.

[3] 2014-Avedøre wastewater Services in Avedøre, Kopenhagen (Denmark) is adding a 1 MW electrolyzer plant to upgrade the anaerobic digestion biogas from sewage sludge.

The company uses an adapted strain of the thermophilic methanogen Methanothermobacter thermautotrophicus and has demonstrated its technology at laboratory-scale in an industrial environment.

[103] [104] The use of the existing natural gas pipelines for hydrogen was studied by the EU NaturalHy project[105] and the United States Department of Energy (DOE).

In 2015 a study published in Energy and Environmental Science found that by using reversible solid oxide cells and recycling waste heat in the storage process, electricity-to-electricity round-trip efficiencies exceeding 70% can be reached at low cost.

[108] In addition, a 2018 study using pressurized reversible solid oxide cells and a similar methodology found that round-trip efficiencies (power-to-power) of up to 80% might be feasible.