Axial-flow pump

An axial-flow pump, or AFP, is a common type of pump that essentially consists of a propeller (an axial impeller) in a pipe.

Fluid particles, in course of their flow through the pump, do not change their radial locations since the change in radius at the entry (called 'suction') and the exit (called 'discharge') of the pump is very small.

An axial flow pump has a propeller-type of impeller running in a casing.

The fluid is pushed in a direction parallel to the shaft of the impeller, that is, fluid particles, in course of their flow through the pump, do not change their radial locations.

The propeller of an axial flow pump is driven by a motor.

Therefore, the maximum energy transfer per unit weight by an axial flow pump =

So, the maximum energy transfer to the fluid per unit weight will be

, therefore to maintain a constant value an equal increase in

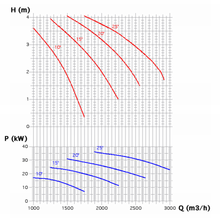

The characteristics of an axial flow pump are shown in the figure.

Also the power requirements and pump head increases with an increase in pitch, thus allowing the pump to adjust according to the system conditions to provide the most efficient operation.

The main advantage of an axial flow pump is that it has a relatively high discharge (flow rate) at a relatively low head (vertical distance).

It also can easily be adjusted to run at peak efficiency at low-flow/high-pressure and high-flow/low-pressure by changing the pitch on the propeller (some models only).

The effect of turning of the fluid is not too severe in an axial pump[4] and the length of the impeller blades is also short.

This leads to lower hydrodynamic losses and higher stage efficiencies.

One of the most common applications of AFPs would be in handling sewage from commercial, municipal and industrial sources.

In sailboats, AFPs are also used in transfer pumps used for sailing ballast.

In power plants, they are used for pumping water from a reservoir, river, lake or sea for cooling the main condenser.

In the chemical industry, they are used for the circulation of large masses of liquid, such as in evaporators and crystallizers.

In sewage treatment, an AFP is often used for internal mixed liquor recirculation (i.e. transferring nitrified mixed liquor from aeration zone to denitrification zone).

In agriculture and fisheries very large horsepower AFPs are used to lift water for irrigation and drainage.

In East Asia, millions of smaller horsepower (6-20 HP) mobile units are powered mostly by single cylinder diesel and petrol engines.

They are used by smaller farmers for crop irrigation, drainage and fisheries.

Impeller designs have improved as well bringing even more efficiency and reducing energy costs to farming there.

Earlier designs were less than two meters long but nowadays they can be up to 6 meters or more to enable them to more safely "reach out" to the water source while allowing the power source (many times two-wheel tractors are used) to be kept in safer, more stable positions, as shown in the adjacent picture.