Rheinisches Braunkohlerevier

The mining of lignite using the open pit method has had a significant impact on the landscape here and led to the formation of several important industrial sites.

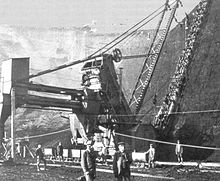

Here, overburden and coal are extracted using large equipment such as bucket wheel excavators, and the pits are then backfilled using large-scale conveyor systems and spreaders.

The seams strike the surface of the Villehorst in the southern district near Brühl or were cut in the impact slope by the Tertiary Rhine or the streams of the foothills.

At the beginning of the general upswing after the Franco-Prussian War of 1870–1871, entrepreneurs in Brühl in 1877 (Friedrich Eduard Behrens with the Roddergrube union) and 1878 (Brühl union) and in 1892 Hermann and his son Carl Gruhl with the Gruhlwerk made coal extraction competitive by means of steam-driven dewatering pumps and revolutionized the production of briquettes by means of mechanical presses.

In 1913, the lignite industry AG Zukunft was founded in the western coalfield as a merger of various small unions with the aim of building a lignite-fired power plant.

On the advice of Reich Economics Minister Hjalmar Schacht, coal liquefaction processes were promoted and Union Rheinischer Braunkohlen Kraftstoff AG was founded in Wesseling in 1937.

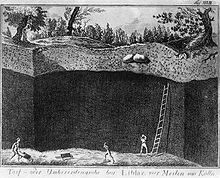

The specially founded Rheinische Braunkohlentiefbaugesellschaft began sinking two shafts between Morschenich and Elsdorf in 1939.. A similar attempt by the Neu-Deutz trade union in Cologne lime around 1850 had failed because of the high groundwater levels.

But the experiment was abandoned as early as 1954: The geological conditions allowed mining only with extreme technical effort, which made the enterprise uneconomical.

The four main tunnels and their side galleries with a total length of eleven kilometers were reinforced with 25,000 cubic meters of concrete and 8300 tons of steel, and the two access shafts were sealed.

Mainly pulverized coal is produced here for use in large industrial firing plants (e.g. cement works, paper mills, sugar refineries).

The laying of the foundation stone on August 23, 2006, was also attended by Minister President Jürgen Rüttgers and German Chancellor Angela Merkel, thus highlighting the importance of the construction.

Press reports in October 2013 indicated that the Group intends to shut down eleven of its lignite-fired power plant units and close the Garzweiler open pit mine by 2018.

Although the company immediately denied that it was withdrawing from the Garzweiler open pit mine, the city of Erkelenz subsequently halted further resettlement plans..

The development of a new open pit mine takes a relatively long time due to the lengthy approval process and the extensive preparatory work, including the necessary resettlements, but then results in secure power generation for decades.

[7][8] The idea received encouragement from physicist Uwe Rau and others.,[8] der RWE Power AG[9] and the Minister for Economic Affairs, Innovation, Digitalization and Energy of North Rhine-Westphalia, Andreas Pinkwart.

The 40-member Lignite Committee is made up of representatives of the municipalities, the Cologne and Düsseldorf regional councils and officials from business and employee organizations.

Particularly controversial recently was the approval for the Garzweiler II open pit mine granted by the SPD government shortly before the 1995 state elections.

The share of fine dust originating from the Hambach open pit mine is given by the NRW State Office for Nature, Environment and Consumer Protection (LANUV) as 25%.

An action plan to reduce particulate matter in the vicinity of the Hambach opencast mine was drawn up under the auspices of the Cologne district government and came into force on September 29, 2005.

Measures to reduce particulate matter in opencast mines: The operation of lignite-fired power plants is associated with high mercury emissions.

[11] Burning lignite in the district's power plants also emits high levels of carbon dioxide, the greenhouse gas mainly responsible for global warming.

The average value in the German electricity mix, including wind, hydro, nuclear and photovoltaic plants, was 530 grams per kilowatt-hour in 2006.

The political disputes surrounding the approval of the Garzweiler II opencast mine also put the RWE Group under public pressure to invest large sums in more efficient power plant technology.

In 2006, BUND described this as a "zero-sum game in terms of climate protection policy"; the new power plant would also continue to burn large amounts of coal.

Due to the enormous volume of lignite mined and the overburden deposited on external dumps, the operator no longer wants to backfill them completely.

However, in the case of Sophienhöhe, which was afforested only twenty years ago, this diversity is attributed to the fact that the forest plant community is still in the process of development.

However, it is a cause for concern that the mining of lignite will result in the loss of sites whose waterlogging provided special growing conditions for plants.

Farmers are often resettled over 30 kilometers or more in the vicinity of freshly recultivated farmland, an undertaking that involves many conversion difficulties and adjustments to the new agricultural conditions.

In the course of open-cast lignite mining, there were numerous important archaeological researches and discoveries, but most of them were only able to open up a fraction of the actual existing sources.

In 2000, for example, an attempt to place the Carl briquette factory in Frechen completely under monument protection in order to be able to show the production process of a historic plant in an exemplary manner failed.