Substation

Substations may be designed and built by a contractor or alternately all phases of its development may be handled by the electrical utility.

In such cases, substation contains high-voltage switches that allow lines to be connected or isolated for fault clearance or maintenance.

A transmission station may have transformers to convert between two transmission voltages, voltage control/power factor correction devices such as capacitors, reactors or static VAR compensators and equipment such as phase shifting transformers to control power flow between two adjacent power systems.

The feeders run along streets overhead (or underground, in some cases) and power the distribution transformers at or near the customer premises.

In distributed generation projects such as a wind farm or photovoltaic power station, a collector substation may be required.

It resembles a distribution substation although power flow is in the opposite direction, from many wind turbines or inverters up into the transmission grid.

The collector substation can also provide power factor correction if it is needed, metering, and control of the wind farm.

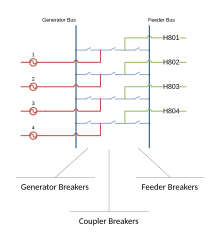

An important function performed by a substation is switching, which is the connecting and disconnecting of transmission lines or other components to and from the system.

De-energizing faulty equipment protects it from further damage, and isolating a fault helps keep the rest of the electrical grid operating with stability.

They are designed to be compact for travel on public roads, and are used for temporary backup in times of natural disaster or war.

Mobile substations are usually rated much lower than permanent installations, and may be built in several units to meet road travel limitations.

Sufficient land area is required for installation of equipment with necessary clearances for electrical safety, and for access to maintain large apparatus such as transformers.

It is a usual practice by many electrical utilities to prepare one-line diagrams with principal elements (lines, switches, circuit breakers, transformers) arranged on the page similarly to the way the apparatus would be laid out in the actual station.

A circuit breaker is used as a protection device to interrupt fault currents automatically, and may be used to switch loads on and off, or to cut off a line when power is flowing in the 'wrong' direction.

With overhead transmission lines, the propagation of lightning and switching surges can cause insulation failures into substation equipment.

These are sets of busbars, usually in multiples of three, since three-phase electrical power distribution is largely universal around the world.

Substations feeding only a single industrial load may have minimal switching provisions, especially for small installations.

[20] Based on the jurisdiction or company,[21] there are safety standards with minimum required clearance between different live equipment or conductors or between live metal and the ground, which often varies with higher clearance being required for higher voltages because of the greater ability to generate flashover.

[23] Sometimes it is necessary to work on parts of the substation while energized, but employees must maintain a safe distance of at least 3 metres (9.8 ft).

[24] The aim to reduce substation footprints comes into conflict with ease of maintenance enhanced by including gaps where employees can safely work.

Indoor substations are usually found in urban areas to reduce the noise from transformers, improve appearance, or protect switchgear from extreme climate or pollution.

Where space is plentiful and appearance of the station is not a factor, steel lattice towers provide low-cost supports for transmission lines and apparatus.

[47] Capacitors can reduce the current in wires, helping stem system losses from voltage drop or enabling extra power to be sent through the conductors.

It often contains protective relays, meters, breaker controls, communications, batteries, and recorders that save detailed data about substation operations, particularly when there is any unusual activity, to help reconstruct what happened after the fact.

[48] Additional equipment is necessary to handle power surges associated with intermittent renewable energy such as dispersed generation from wind or solar.

Auxiliary losses are due to running fans and pumps[50] which is noisy when the transformer is operating at maximum capacity.

[53] Maintenance of substations involves inspections, data collection and analysis, and routine scheduled work.

Dissolved gas analysis can tell when an oil-insulated transformer needs to have the oil filtered or replace, and also detect other issues.

As the complexity of distribution networks grew, it became economically necessary to automate supervision and control of substations from a centrally attended point, to allow overall coordination in case of emergencies and to reduce operating costs.

Early efforts to remote control substations used dedicated communication wires, often run alongside power circuits.

- Primary power lines' side

- Secondary power lines' side

- Primary power lines

- Ground wire

- Overhead lines

- Potential transformer

- Disconnect switch

- Circuit breaker

- Current transformer

- Lightning arrester

- Main transformer

- Control building

- Security fence

- Secondary power lines