Highway engineering

The growth of commerce, educational institutions, housing, and defense have largely drawn from government budgets in the past, making the financing of public highways a challenge.

However, improperly planned, designed, constructed, and maintained highways can disrupt the social and economic characteristics of any size community.

This process is known as an Environmental Impact Assessment, or EIA, as it systematically deals with the following elements:[6] Highway systems generate the highest price in human injury and death, as nearly 50 million persons are injured in traffic accidents every year, not including the 1.2 million deaths.

Human factors include reaction time for braking and steering, visual acuity for traffic signs and signals, and car-following behaviour.

[9] There are certain considerations that must be properly addressed in the design process to successfully fit a highway to a site's topography and maintain its safety.

[9] The materials used for roadway construction have progressed with time, dating back to the early days of the Roman Empire.

The subbase is generally constructed from local aggregate material, while the top of the subgrade is often stabilized with cement or lime.

The term "flexible" is used because of the asphalts ability to bend and deform slightly, then return to its original position as each traffic load is applied and removed.

[12] One major design consideration of rigid pavements is reducing fatigue failure due to the repeated stresses of traffic.

Fatigue failure is common among major roads because a typical highway will experience millions of wheel passes throughout its service life.

In addition to design criteria such as traffic loadings, tensile stresses due to thermal energy must also be taken into consideration.

Due to the relatively low tensile strength of concrete, thermal stresses are extremely important to the design considerations of rigid pavements.

[12] Rigid pavements are generally constructed in three layers - a prepared subgrade, base or subbase, and a concrete slab.

High temperatures and moisture stresses within the pavement creates cracking, which the reinforcing steel holds tightly together.

At transverse joints, dowel bars are typically placed to assist with transferring the load of the vehicle across the cracking.

CRCPs solely rely on continuous reinforcing steel to hold the pavement's natural transverse cracks together.

Prestressed pavements allow for a thinner slab thickness by partly or wholly neutralizing thermally induced stresses or loadings.

The required overlay thickness for a structurally sound rigid pavement is much smaller than for one that has reached the end of its service life.

The highway engineer must determine which situations a particular design process should be applied, usually a combination of several appropriate methods and materials to direct water away from the structure.

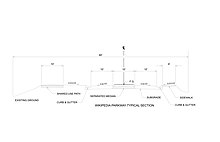

Highways must be designed with a slope or crown so that runoff water will be directed to the shoulder of the road, into a ditch, and away from the site.

This advancement in technology has raised the level of skill sets required to manage highway construction projects.

[18] Some examples of each are listed below: Typically, construction begins at the lowest elevation of the site, regardless of the project type, and moves upward.

The subbase thickness is generally in the range of 4 to 16 inches, and it is designed to withstand the required structural capacity of the pavement section.

[18] Common materials used for a highway subbase include gravel, crushed stone, or subgrade soil that is stabilized with cement, fly ash, or lime.

[18] Heavy loads are continuously applied to pavement surfaces, and the base layer absorbs the majority of these stresses.

These treatments provide improved support for heavy loads, frost susceptibility, and serves as a moisture barrier between the base and surface layers.

[18] There are two most commonly used types of pavement surfaces used in highway construction: hot-mix asphalt and Portland cement concrete.

This coat bonds loose material, creating a cohesive layer between the base course and asphalt surface.

Tack coats are typically applied on adjacent pavements (curbs) to assist the bonding of the HMA and concrete.

In predictive maintenance planning empirical, data-driven methods give more accurate results than mechanical models.