Truss

Although this rigorous definition allows the members to have any shape connected in any stable configuration, architectural trusses typically comprise five or more triangular units constructed with straight members whose ends are connected at joints referred to as nodes.

[4] Truss derives from the Old French word trousse, from around 1200 AD, which means "collection of things bound together".

[5][6] The term truss has often been used to describe any assembly of members such as a cruck frame[7][8] or a couple of rafters.

[9][10] A truss consists of typically (but not necessarily) straight members connected at joints, traditionally termed panel points.

This type of truss is seen in a framed roof consisting of rafters and a ceiling joist,[13] and in other mechanical structures such as bicycles and aircraft.

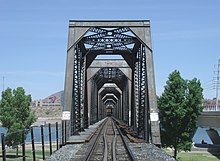

[16] The depth of a truss, or the height between the upper and lower chords, is what makes it an efficient structural form.

A solid girder or beam of equal strength would have substantial weight and material cost as compared to a truss.

A tetrahedron shape is the simplest space truss, consisting of six members that meet at four joints.

Therefore, for given planar truss with a fixed depth, the Pratt configuration is usually the most efficient under static, vertical loading.

The Wright Flyer used a Pratt truss in its wing construction, as the minimization of compression member lengths allowed for lower aerodynamic drag.

His design, patented in 1820 and 1835, uses easy-to-handle planks arranged diagonally with short spaces in between them, to form a lattice.

Thousands of bowstring trusses were used during World War II for holding up the curved roofs of aircraft hangars and other military buildings.

The primary difference is the horizontal extension at the centre which relies on beam action to provide mechanical stability.

It is rarely used for bridges because of higher costs compared to a triangulated truss, but in buildings it has the advantage that a large amount of the exterior envelope remains unobstructed and it can therefore be used for windows and door openings.

Trusses that are supported at more than two positions are said to be statically indeterminate, and the application of Newton's Laws alone is not sufficient to determine the member forces.

While the relation (a) is necessary, it is not sufficient for stability, which also depends on the truss geometry, support conditions and the load carrying capacity of the members.

Because the forces in each of its two main girders are essentially planar, a truss is usually modeled as a two-dimensional plane frame.

The analysis of trusses often assumes that loads are applied to joints only and not at intermediate points along the members.

Provided that the members are long and slender, the moments transmitted through the joints are negligible, and the junctions can be treated as "hinges" or "pin-joints".

Trusses are physically stronger than other ways of arranging structural elements, because nearly every material can resist a much larger load in tension or compression than in shear, bending, torsion, or other kinds of force.

Individually, they are also in tension and compression, the exact arrangement of forces is depending on the type of truss and again on the direction of bending.

In the adjacent picture, the top chord is prevented from buckling by the presence of bracing and by the stiffness of the web members.

In other cases the appearance of the structure may take on greater importance and so influence the design decisions beyond mere matters of economics.

Wood posts enable the fabrication of strong, direct, yet inexpensive connections between large trusses and walls.

Solid-sawn timber and glulam posts are generally notched to form a truss bearing surface.