Screwdriver

Handles are typically wood, metal, or plastic[1] and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down.

Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically.

A screwdriver is classified by its tip, which is shaped to fit the driving surfaces (slots, grooves, recesses, etc.)

The two most common are the simple 'blade'-type for slotted screws, and Phillips, generically called "cross-recess", "cross-head", or "cross-point".

Many options and enhancements, such as built-in bubble levels, high/low gear selection, magnetic screw holders, adjustable-torque clutches, keyless chucks, "gyroscopic" control, etc., are available.

The tool's original names in German and French were Schraubenzieher[2][3][4][circular reference] (screw-tightener) and tournevis (turnscrew), respectively.

The screwdriver remained inconspicuous, however, as evidence of its existence throughout the next 300 years is based primarily on the presence of screws.

Screws were used in the 15th century to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock.

Refinement of the precision of screws also significantly contributed to the boom in production, mostly by increasing its efficiency and standardizing sizes, important precursors to industrial manufacture.

Socket screws rapidly grew in popularity, and are still used for their resistance to wear and tear, compatibility with hex keys, and ability to stop a power tool when set.

Though immensely popular, Robertson had trouble marketing his invention to the newly booming auto industry, for he was unwilling to relinquish his patents.

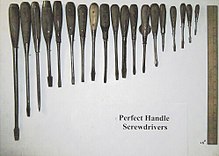

The "Perfect Pattern Handle"[further explanation needed] screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900.

Designs include indentations for the user's fingers, and surfaces of a soft material such as thermoplastic elastomer to increase comfort and grip.

Some screwdrivers have a short hexagonal section at the top of the blade, adjacent to the handle, so that a ring spanner or open wrench can be used to increase the applied torque.

The offset screwdriver has a handle set at right angles to the small blade, providing access to narrow spaces and giving extra torque.

The tool used to drive a slotted screw head is called a standard, common blade, flat-blade, slot-head, straight, flat, flat-tip,[6] or "flat-head"[7] screwdriver.

This last usage can be confusing, because the term flat-head also describes a screw with a flat top, designed to install in a countersunk hole.

The more common type is sometimes called keystone, where the blade profile is slightly flared before tapering off at the end, which provides extra stiffness to the workface and makes it capable of withstanding more torque by gripping deeper in the screw slot.

instruct mechanics to grind down the tip of the blade, which, due to the taper, increases its thickness and consequently allows more precise engagement with the slot in the screw.

(The taper's earliest reason for being was to make the manufacture of the screws practical using cold forming of the heads,[17] but its other advantages helped popularize the drive.)

The socket-headed Robertson screws are self-centering, reduce cam out, stop a power tool when set, and can be removed if painted over or old and rusty.

Henry Ford found them highly reliable and saved considerable production time, but he could not secure licensing for them in the United States, so he limited their use solely to his Canadian division.

It is often claimed that they can apply more torque than any of the other commonly used cross-head screwdriver systems, due to a complex fluting (mating) configuration.

Compatible screw heads are usually identifiable by a single depressed dot or an "X" to one side of the cross slot.

The main cause of this trend is manufacturing efficiency: Torx screwdriver tips do not slip out of the fastener as easily as would a Phillips or slotted driver.

Another type of security head has smooth curved surfaces instead of the slot edges that would permit loosening the screw; it is found in public rest room privacy partitions, and cannot be removed by conventional screwdrivers.

The user pushes the handle toward the workpiece, causing a pawl in a spiral groove to rotate the shank and the removable bit.

Once very popular, versions of these spiral ratchet drivers using proprietary bits have been largely discontinued by manufacturers such as Stanley.