Shear wall

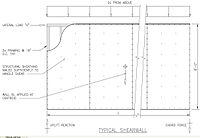

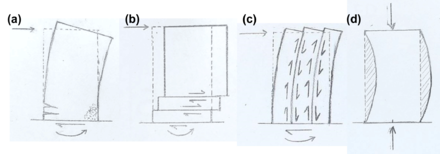

A shear wall is an element of a structurally engineered system that is designed to resist in-plane lateral forces, typically wind and seismic loads.

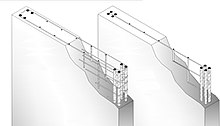

While plywood is the conventional material used in wood (timber) shear walls, advances in technology and modern building methods have produced prefabricated options such as sheet steel and steel-backed shear panels used for narrow walls bracketing an opening that have proven to provide stronger seismic resistance.

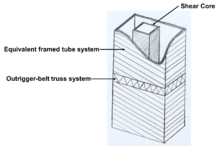

It is considered as a primary structure which provides relatively stiff resistance to vertical and horizontal forces acting in its plane.

The factors determining the failure mechanism include geometry, loading, material properties, restraint, and construction.

Shear walls may also be constructed using light-gauge steel diagonal bracing members tied to collector and ancor points.

Two neighboring wall panels can be considered coupled when the interface transfers longitudinal shear to resist the deformation mode.

The location of a shear wall significantly affects the building function, such as natural ventilation and daylighting performance.

Construction codes of practice define maximum and minimum amounts of reinforcement as well as the detailing of steel bars.

Tunnel form construction uses a formwork system to cast slabs and walls as a single pour operation.

The advantage of this method is that the construction can progress vertically and horizontally at the same time, thereby increasing the integrity and stability of the structure.

Modeling techniques have been progressively updated during the last two decades, moving from linear static to nonlinear dynamic, enabling more realistic representation of global behavior, and different failure modes.