Shore durometer

The Shore durometer is a device for measuring the hardness of a material, typically of polymers.

[1] Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials.

Lower numbers indicate less resistance and softer materials.

The term is also used to describe a material's rating on the scale, as in an object having a "'Shore durometer' of 90."

The scale was defined by Albert Ferdinand Shore, who developed a suitable device to measure hardness in the 1920s.

The image of Bareiss digital durometer is shown in the photo.

However, the ASTM D2240-00 testing standard calls for a total of 12 scales, depending on the intended use: types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. Each scale results in a value between 0 and 100, with higher values indicating a harder material.

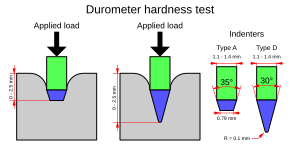

[2] Durometer, like many other hardness tests, measures the depth of an indentation in the material created by a given force on a standardized presser foot.

This depth is dependent on the hardness of the material, its viscoelastic properties, the shape of the presser foot, and the duration of the test.

The basic test requires applying the force in a consistent manner, without shock, and measuring the hardness (depth of the indentation).

The material under test should be a minimum of 6 mm (0.25 inches) thick.

[4] The ASTM D2240 standard recognizes twelve different durometer scales using combinations of specific spring forces and indentor configurations.

The R designation specifies a presser foot diameter (hence the R, for radius; obviously D could not be used) of 18 ± 0.5 mm (0.71 ± 0.02 in) in diameter, while the spring forces and indenter configurations remain unchanged.

[5] Some conditions and procedures that have to be met, according to DIN ISO 7619-1 standard are: The final value of the hardness depends on the depth of the indenter after it has been applied for 15 seconds on the material.

If the indenter penetrates 2.54 mm (0.100 inch) or more into the material, the durometer is 0 for that scale.

The measurement must be redone with adjacent scale type.

[1] Using linear elastic indentation hardness, a relation between the ASTM D2240 hardness and the Young's modulus for elastomers has been derived by Gent[7].Gent's relation has the form

Mix and Giacomin derive comparable equations for all 12 scales that are standardized by ASTM D2240.

is in units of Pa. To make that a little more insightful, here is a list of Shore A values with their corresponding Young's modulus (in MPa), where "MPa" is computed from "ShoreA" using first formula, and then "AltShoreA" is computed from "MPa" using second formula : A first-order estimate of the relation between ASTM D2240 type D hardness (for a conical indenter with a 15° half-cone angle) and the elastic modulus of the material being tested is[10]

Another Neo-Hookean linear relation between the ASTM D2240 hardness value and material elastic modulus has the form[10]