Silicone

Silicon is a chemical element, a hard dark-grey semiconducting metalloid, which in its crystalline form is used to make integrated circuits ("electronic chips") and solar cells.

Alfred Stock and Carl Somiesky examined the hydrolysis of dichlorosilane, a reaction that was proposed to initially give the monomer H2SiO:

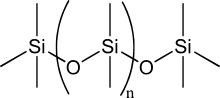

Branches or crosslinks in the polymer chain can be introduced by using organosilicone precursors with fewer alkyl groups, such as methyl trichlorosilane and methyltrimethoxysilane.

Similarly, precursors with three methyl groups can be used to limit molecular weight, since each such molecule has only one reactive site and so forms the end of a siloxane chain.

Ullmann's Encyclopedia of Industrial Chemistry lists the following major categories of application: Electrical (e.g. insulation), electronics (e.g., coatings), household (e.g., sealants and cooking utensils), automobile (e.g. gaskets), airplane (e.g., seals), office machines (e.g. keyboard pads), medicine and dentistry (e.g. tooth impression molds), textiles and paper (e.g. coatings).

Automotive body manufacturing plants and paint shops avoid silicones, as trace contamination may cause "fish eyes", which are small, circular craters which mar a smooth finish.

[citation needed] Silicones in combination with thermoplastics provide improvements in scratch and mar resistance and lowered coefficient of friction.

Maintaining extreme functionality is paramount for passenger safety in the aerospace industry, so each component on an aircraft requires high-performance materials.

Silicone rubber can be molded with tight tolerances ensuring gaskets form airtight seals both on the ground and in the air, where atmospheric pressure decreases.

As the nature of air travel results in much noise and vibration, powerful engines, landings, and high speeds all need to be considered to ensure passenger comfort and safe operation of the aircraft.

In plumbing, silicone grease is typically applied to O-rings in brass taps and valves, preventing lime from sticking to the metal.

[citation needed] Silicone membranes have been used to cover and restore industrial roofs, thanks to its extreme UV resistance, and ability to keep their waterproof performance for decades.

[citation needed] Silicone rubber can be 3D printed (liquid deposition modelling, LDM) using pump-nozzle extrusion systems.

[citation needed] Electronic components are sometimes encased in silicone to increase stability against mechanical and electrical shock, radiation and vibration, a process called "potting".

Silicones are used where durability and high performance are demanded of components under extreme environmental conditions, such as in space (satellite technology).

Silicones also have the advantage of little exothermic heat rise during cure, low toxicity, good electrical properties, and high purity.

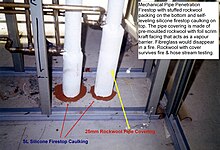

Silicone foam has been used in North American buildings in an attempt to firestop openings within the fire-resistance-rated wall and floor assemblies to prevent the spread of flames and smoke from one room to another.

Silicone-foam firestops have been the subject of controversy and press attention due to smoke development from pyrolysis of combustible components within the foam, hydrogen gas escape, shrinkage, and cracking.

Polydimethylsiloxane (PDMS) is often used for this purpose, since its specific crosslinking results in a flexible and soft silicone with high durability and tack.

Addition and condensation (e.g. polyvinyl siloxane) silicones find wide application as a dental impression material due to its hydrophobic property and thermal stability.

Some silicones, notably the amine functionalized amodimethicones, are excellent hair conditioners, providing improved compatibility, feel, and softness, and lessening frizz.

The phenyl dimethicones, in another silicone family, are used in reflection-enhancing and color-correcting hair products, where they increase shine and glossiness (and possibly impart subtle color changes).

However, if included in the same formulation, amodimethicone and phenyltrimethicone interact and dilute each other, making it difficult to achieve both high shine and excellent conditioning in the same product.

[23] Silicone rubber is commonly used in baby bottle nipples (teats) for its cleanliness, aesthetic appearance, and low extractable content.

This substance is noted for its unusual characteristics, e.g., that it bounces, but breaks when given a sharp blow; it will also flow like a liquid and form a puddle given enough time.

Glass joints made with silicone sealant can withstand great pressure, making obsolete the original aquarium construction method of angle-iron and putty.

[27] Silicone is used in special effects as a material for simulating realistic skin, either for prosthetic makeup, prop body parts, or rubber masks.

[28] Platinum silicones are ideal for simulating flesh and skin due to their strength, firmness, and translucency, creating a convincing effect.

However, the doses required for inhibition are by orders of magnitude higher than the ones resulting from the accumulated exposure to consumer products containing cyclomethicone.

[42][43] Compounds containing silicon–oxygen double bonds, now called silanones, but which could deserve the name "silicone", have long been identified as intermediates in gas-phase processes such as chemical vapor deposition in microelectronics production, and in the formation of ceramics by combustion.