Foam latex

Single use plastics and polymer foams are often disposed of in landfills, and there is a growing concern about the amount of space this waste takes up.

[8] In an effort to make the foams more environmentally friendly, research is being done into fillers than can achieve the same enhancements as mineral while also increasing biodegradability of the product.

Other advantages of the continuous process is the decreased labor cost and lowered waste product from the mold.

The continuous process includes the use of a machine with different chambers for the creation and foaming of the mixture, addition of fillers, and molding and curing.

The shape of different regions of the curve will reflect some important quality of the foam relating to compression or relaxation stress and strain behaviour of the material.

[13] Relating to the longevity of the material, the resistance to dynamic fatigue is tested by recursively compressing a foam and allowing it to relax.

[13] There are several ways conductivity can be affected through these factors: Energy absorption is a particularly important quality of latex foam.

In this case, most of the absorption occurs in the second region of the curve caused by the deformation and crushing of cell walls.

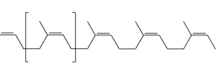

Styrene-butadiene rubber latex rose to prominence once high-solids concentrates, which were designed specifically for foaming, began to be sold on the market.

Properties of this polymer were fairly similar to natural rubber latex, so the competition between the two choices here is mostly economical.

However, adding fillers also affects the desirable properties of the latex foam, such as by decreasing extension at break and resistance to repeated occurrences of stress and relaxation.

Wet-ground micas can similarly be added into the latex during foaming, and they tend to have a lower impact on tensile strength and extension at break.

Such fillers include chlorinated paraffin hydrocarbons, antimony trioxide, zinc borate, and hydrated aluminum oxide.

[15] These are materials that improve the structural properties of latex foam while also making it more environmentally friendly through increased biodegradability.

[8][9] Eggshell powder is an example of such a filler which can be added into the latex foam to manipulate the properties of the product and increase its environmental friendliness.

This was also found to increase the biodegradability of the foam for improved control over post-consumer waste of these products.

[8] Due to their energy absorption properties, latex foams are useful for transportation applications, such as in packaging to decrease impact on the shipped product or in vehicle upholstery.

[6] Latex foams can be used in items like bedding, upholstery, and pillows for cushioning purposes due to their expressed stress-strain curve when experiencing a load.

Due to their containing of air bubbles, latex foams carry some soundproofing properties.

[16] Foam latex is used in masks and facial prosthetics to change a person's outward appearance.

It can be used in various arts and crafts including puppetry and costumes because of its ability to pick up small details of painting as well as its strength.

The material has proven to be the most effective way of allowing players to grip the football in wet and dry playing conditions, as well as providing damping properties which help in catching.