Multi-junction solar cell

The use of multiple semiconducting materials allows the absorbance of a broader range of wavelengths, improving the cell's sunlight to electrical energy conversion efficiency.

Traditional photovoltaic cells are commonly composed of doped silicon with metallic contacts deposited on the top and bottom.

Hence, the operating point (Vm, Jm) is located in the region where V > 0 and Iph < 0, and chosen to maximize the absolute value of the power |P|.

This is a major consideration for conventional solar cells, which are not sensitive to most of the infrared spectrum, although that represents almost half of the power coming from the sun.

Practical concerns further reduce this, notably reflection off the front surface or the metal terminals, with modern high-quality cells at about 22%.

An analysis of the AM1.5 spectrum, shows the best balance is reached at about 1.1 eV (about 1100 nm, in the near infrared), which happens to be very close to the natural bandgap in silicon and a number of other useful semiconductors.

Producing a tandem cell is not an easy task, largely due to the thinness of the materials and the difficulties extracting the current between the layers.

This technique is widely used by amorphous silicon solar cells, Uni-Solar's products use three such layers to reach efficiencies around 9%.

[17] The choice of materials for each sub-cell is determined by the requirements for lattice-matching, current-matching, and high performance opto-electronic properties.

This constraint has been relaxed somewhat in recently developed metamorphic solar cells which contain a small degree of lattice mismatch.

However, a greater degree of mismatch or other growth imperfections can lead to crystal defects causing a degradation in electronic properties.

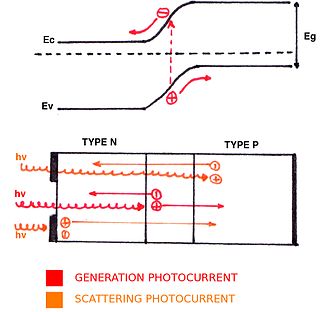

The materials are ordered with decreasing bandgaps, Eg, allowing sub-bandgap light (hc/λ < eEg) to transmit to the lower sub-cells.

Because the different layers are closely lattice-matched, the fabrication of the device typically employs metal-organic chemical vapor deposition (MOCVD).

This technique is preferable to the molecular beam epitaxy (MBE) because it ensures high crystal quality and large scale production.

The main goal of tunnel junctions is to provide a low electrical resistance and optically low-loss connection between two subcells.

are then given by the J-V diode equation: We can estimate the limiting efficiency of ideal infinite multi-junction solar cells using the graphical quantum-efficiency (QE) analysis invented by C. H.

[28] To fully take advantage of Henry's method, the unit of the AM1.5 spectral irradiance should be converted to that of photon flux (i.e., number of photons/m2·s).

However, the current graphical QE analysis still cannot reflect the second intrinsic loss in the efficiency of solar cells, radiative recombination.

Now, we can fully use Henry's graphical QE analysis, taking into account the two major intrinsic losses in the efficiency of solar cells.

The shaded area under the red line represents the maximum work done by ideal infinite multi-junction solar cells.

Adding aluminium to the top cell increases its band gap to 1.96 eV,[39] covering a larger part of the solar spectrum and obtain a higher open-circuit voltage VOC.

[24] The exponential relationship implies that as the cell approaches the limit of efficiency, the increase cost and complexity grow rapidly.

Currently, there are several commercial (non-Perovskite) multi-junction technologies including tandems and triple- and quadruple-junction modules that typically use III–V semiconductors, with promising power conversion efficiency that rival and even outperform the benchmark silicon solar cells.

[43][44] Using concentrations on the order of 500 to 1000, meaning that a 1 cm2 cell can use the light collected from 0.1 m2 (as 1 m2 equal 10000 cm2), produces the highest efficiencies seen to date.

For this reason, almost all multi-junction cell research for terrestrial use is dedicated to concentrator systems, normally using mirrors or Fresnel lenses.

Using a concentrator also has the added benefit that the number of cells needed to cover a given amount of ground area is greatly reduced.

As of 2014 multi-junction cells were expensive to produce, using techniques similar to semiconductor device fabrication, usually metalorganic vapour phase epitaxy but on "chip" sizes on the order of centimeters.

Physically, the main property of a MJ solar cell is having more than one pn junction in order to catch a larger photon energy spectrum while the main property of the thin film solar cell is to use thin films instead of thick layers in order to decrease the cost efficiency ratio.

[24] As less expensive multi-junction materials become available other applications involve bandgap engineering for microclimates with varied atmospheric conditions.

[citation needed] In terrestrial concentrating applications, the scatter of blue light by the atmosphere reduces the photon flux above 1.87 eV, better balancing the junction currents.