Transgranular fracture

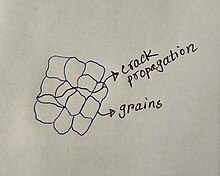

This type of fracture typically results from a combination of high stresses and material defects, such as voids or inclusions, that create a path for crack propagation through the grains.

A broad range of ductile or brittle materials, including metals, ceramics, and polymers, can experience transgranular fracture.

When examined under scanning electron microscopy, this type of fracture reveals cleavage steps, river patterns, feather markings, dimples, and tongues.

[3] However, some general steps are typically involved in the transgranular fracture process: In ductile metals, the plastic deformation of the material can be a critical factor in the transgranular fracture process, while in brittle materials such as ceramics, the formation and growth of cracks can be influenced by factors such as grain size, porosity, and the presence of impurities or other defects.

Additionally, the precipitates altered the stress distribution within the material, promoting transgranular crack propagation instead.