Yield surface

This is because stress states that lie outside the yield surface are non-permissible in rate-independent plasticity, though not in some models of viscoplasticity.

[1] The yield surface is usually expressed in terms of (and visualized in) a three-dimensional principal stress space (

), are usually used to describe yield surfaces for cohesive frictional materials such as rocks, soils, and ceramics.

Figure 1 shows the Tresca–Guest yield surface in the three-dimensional space of principal stresses.

This means that the material remains elastic when all three principal stresses are roughly equivalent (a hydrostatic pressure), no matter how much it is compressed or stretched.

In such situations, if the shear stress reaches the yield limit then the material enters the plastic domain.

Figure 2 shows the Tresca–Guest yield surface in two-dimensional stress space, it is a cross section of the prism along the

Figure 3 shows the von Mises yield surface in the three-dimensional space of principal stresses.

It is a circular cylinder of infinite length with its axis inclined at equal angles to the three principal stresses.

Figure 4 shows the von Mises yield surface in two-dimensional space compared with Tresca–Guest criterion.

represents the general equation of a second order surface of revolution about the hydrostatic axis.

Some special case are:[15] The relations compression-tension and torsion-tension can be computed to The Poisson's ratios at tension and compression are obtained using For ductile materials the restriction is important.

The application of rotationally symmetric criteria for brittle failure with has not been studied sufficiently.

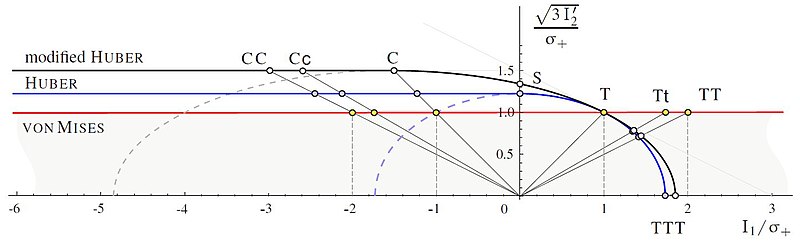

For practical applications, the third invariant of the deviator in the odd and even power should be introduced in the equation, e.g.:[17] The Huber criterion consists of the Beltrami ellipsoid and a scaled von Mises cylinder in the principal stress space,[18][19][20][21] see also[22][23] with

[26] consists of the Schleicher ellipsoid with the restriction of Poisson's ratio at compression and a cylinder with the

are the yield (failure) stresses of the material in uniaxial compression and tension, respectively.

Figure 5 shows Mohr–Coulomb yield surface in the three-dimensional space of principal stresses.

Figure 7 shows Drucker–Prager yield surface in the three-dimensional space of principal stresses.

[28] The Drucker-Prager yield criterion is also commonly expressed in terms of the material cohesion and friction angle.

gives the yield surface an ellipsoidal cross section when viewed from a direction perpendicular to its axis.

The yield criterion has the functional form However, it is more commonly expressed in Haigh–Westergaard coordinates as The cross-section of the surface when viewed along its axis is a smoothed triangle (unlike Mohr–Coulomb).

The Rosendahl criterion [37][38][39] reads with the shape function of hexagonal symmetry in the

The criteria of Podgórski and Rosendahl describe single surfaces in principal stress space without any additional outer contours and plane intersections.

Note that in order to avoid numerical issues the real part function

-substitution [23] which is sufficient for many applications, e.g. metals, cast iron, alloys, concrete, unreinforced polymers, etc.

The seven, non-negative material parameters: define the shape of the meridian and deviatoric sections.

This criterion represents a smooth and convex surface, which is closed both in hydrostatic tension and compression and has a drop-like shape, particularly suited to describe frictional and granular materials.

The following criterion of isotropic material behavior contains a number of other well-known less general criteria, provided suitable parameter values are chosen.

Since 1989 Frederic Barlat has developed a family of yield functions for constitutive modelling of plastic anisotropy.

Among them, Yld2000-2D yield criteria has been applied for a wide range of sheet metals (e.g., aluminum alloys and advanced high-strength steels).