Turbomachinery

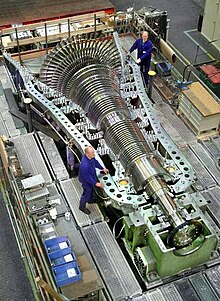

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors.

[3] These two types of machines are governed by the same basic relationships including Newton's second Law of Motion and Euler's pump and turbine equation for compressible fluids.

Centrifugal pumps are also turbomachines that transfer energy from a rotor to a fluid, usually a liquid, while turbines and compressors usually work with a gas.

[1] The first turbomachines could be identified as water wheels, which appeared between the 3rd and 1st centuries BCE in the Mediterranean region.

Furthermore, steam turbines accounted for roughly 45% of electrical power generated in the United States in 2021.

[4] Then the first functioning industrial gas turbines were used in the late 1890s to power street lights (Meher-Homji, 2000).

[6] In contrast to positive displacement machines (particularly of the reciprocating type which are low speed machines based on the mechanical and volumetric efficiency considerations), the majority of turbomachines run at comparatively higher speeds without any mechanical problems and volumetric efficiency close to one hundred percent.

A radial turbomachine can be inward or outward flow type depending on the purpose that needs to be served.

The outward flow type increases the energy level of the fluid and vice versa.

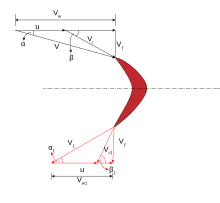

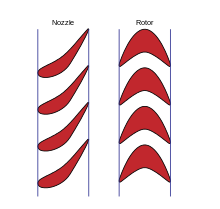

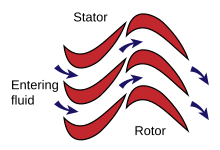

Turbomachines can finally be classified on the relative magnitude of the pressure changes that take place across a stage:[2][5] Impulse Turbomachines operate by accelerating and changing the flow direction of fluid through a stationary nozzle (the stator blade) onto the rotor blade.

Reaction Turbomachines operate by reacting to the flow of fluid through aerofoil shaped rotor and stator blades.

The velocity of the fluid through the sets of blades increases slightly (as with a nozzle) as it passes from rotor to stator and vice versa.

For compressible working fluids, multiple turbine stages are usually used to harness the expanding gas efficiently.

Hydro electric - Hydro-electric turbomachinery uses potential energy stored in water to flow over an open impeller to turn a generator which creates electricity Steam turbines - Steam turbines used in power generation come in many different variations.

The overall principle is high pressure steam is forced over blades attached to a shaft, which turns a generator.

As the steam travels through the turbine, it passes through smaller blades causing the shaft to spin faster, creating more electricity.

They run just like gas turbines for power generation, but are also much smaller and do require more machinery for propulsion.

Pumps are used to move fluids around using some sort of mechanical power, from electric motors to full size diesel engines.

One of the most common solutions to this issue is to use a turbopump that extracts energy from an energetic fluid flow.

The source of this energetic fluid flow could be one or a combination of many things, including the decomposition of hydrogen peroxide, the combustion of a portion of the propellants, or even the heating of cryogenic propellants run through coolant jackets in the combustion chamber's walls.

Certainly there are significant differences between these machines and between the types of analysis that are typically applied to specific cases.