Weld access hole

The hole also minimizes the induction of thermal stresses with a combination of partially releasing the welded section, avoiding welding the T section where the flange joins the web and improving cooling conditions.

[1][2] The configuration adopted for web access holes affects how the beam joint will bend when under stress.

CJP welds extend completely through the thickness of components joined.

A CJP weld transmits the full load-carrying capacity of the structural components joined,[4] and is important for seismic safety.

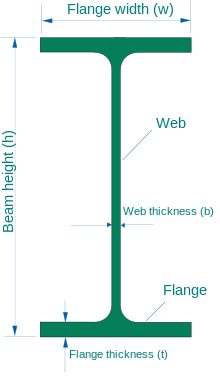

Weld access holes in the web of a beam make it possible to weld both sides of a flange, making the flange joint stronger, at the expense of the web joint.