I-beam

Technical terms for similar items include H-beam, I-profile, universal column (UC), w-beam (for "wide flange"), universal beam (UB), rolled steel joist (RSJ), or double-T (especially in Polish, Bulgarian, Spanish, Italian, and German).

The Euler–Bernoulli beam equation shows that the Ɪ-shaped section is a very efficient form for carrying both bending and shear loads in the plane of the web.

On the other hand, the cross-section has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

In 1849, the method of producing an I-beam, as rolled from a single piece of wrought iron,[1] was patented by Alphonse Halbou of Forges de la Providence in Marchienne-au-Pont, Belgium.

UCs have equal or near-equal width and depth and are more suited to being oriented vertically to carry axial load such as columns in multi-storey construction, while UBs are significantly deeper than they are wide are more suited to carrying bending load such as beam elements in floors.

I-joists, I-beams engineered from wood with fiberboard or laminated veneer lumber, or both, are also becoming increasingly popular in construction, especially residential, as they are both lighter and less prone to warping than solid wooden joists.

Design may be governed by any of the following criteria: A beam under bending sees high stresses along the axial fibers that are farthest from the neutral axis.

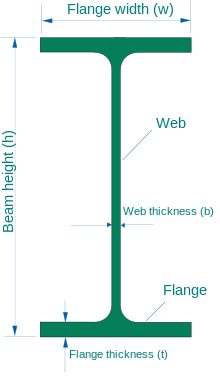

This observation is the basis of the I-beam cross-section; the neutral axis runs along the center of the web which can be relatively thin and most of the material can be concentrated in the flanges.

Since the section modulus depends on the value of the moment of inertia, an efficient beam must have most of its material located as far from the neutral axis as possible.

When designing a symmetric I-beam to resist stresses due to bending the usual starting point is the required section modulus.

[4] For this cross-section, However, these ideal conditions can never be achieved because material is needed in the web for physical reasons, including to resist buckling.

In Mexico, steel I-beams are called IR and commonly specified using the depth and weight of the beam in metric terms.

A cellular beam is up to 1.5 times stronger than its parent section and is therefore utilized to create efficient large span constructions.