Wire

[1] In antiquity, jewelry often contained large amounts of wire in the form of chains and applied decoration that was accurately made and which must have been produced by some efficient, if not technically advanced, means.

In some cases, strips cut from metal sheet were made into wire by pulling them through perforations in stone beads.

The strip twist wire manufacturing method was superseded by drawing in the ancient Old World sometime between about the 8th and 10th centuries AD.

Swaging is of great antiquity, possibly dating to the beginning of the 2nd millennium BCE in Egypt and in the Bronze and Iron Ages in Europe for torcs and fibulae.

The wire was used to make wool cards and pins, manufactured goods whose import was prohibited by Edward IV in 1463.

[5] The first wire mill in Great Britain was established at Tintern in about 1568 by the founders of the Company of Mineral and Battery Works, who had a monopoly on this.

According to a description in the early 20th century, "[w]ire is usually drawn of cylindrical form; but it may be made of any desired section by varying the outline of the holes in the draw-plate through which it is passed in the process of manufacture.

The object of utilising precious stones is to enable the dies to be used for a considerable period without losing their size, and so producing wire of incorrect diameter.

After a number of passes the wire may be annealed to facilitate more drawing or, if it is a finished product, to maximise ductility and conductivity.

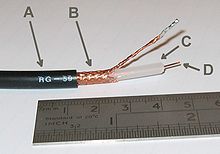

The wire or cable may be further protected with substances like paraffin, some kind of preservative compound, bitumen, lead, aluminum sheathing, or steel taping.

Some of the smallest machines for cotton covering have a large drum, which grips the wire and moves it through toothed gears; the wire passes through the centre of disks mounted above a long bed, and the disks carry each a number of bobbins varying from six to twelve or more in different machines.

A supply of covering material is wound on each bobbin, and the end is led on to the wire, which occupies a central position relatively to the bobbins; the latter being revolved at a suitable speed bodily with their disks, the cotton is consequently served on to the wire, winding in spiral fashion so as to overlap.

The various strands coming from the spools at various parts of the circumference of the cage all lead to a disk at the end of the hollow shaft.

Toothed gears having certain definite ratios are used to cause the winding drum for the cable and the cage for the spools to rotate at suitable relative speeds which do not vary.

Solid wire also provides mechanical ruggedness; and, because it has relatively less surface area which is exposed to attack by corrosives, protection against the environment.

For better performance at high frequencies, litz wire, which has the individual strands insulated and twisted in special patterns, may be used.

For applications with constant repeated movement, such as assembly robots and headphone wires, 70 to 100 is mandatory [citation needed].

Vast quantities of aluminium, copper, nickel and steel wire are employed for telephone and data cables, and as conductors in electric power transmission, and heating.

The metals must in the first place be ductile and strong in tension, the quality on which the utility of wire principally depends.

Such musical strings are said to be "overspun"; the added wire may be circular in cross-section ("round-wound"), or flattened before winding ("flat-wound").