3D printing processes

Some of the different types of physical transformations which are used in 3D printing include melt extrusion, light polymerization, continuous liquid interface production and sintering.

These usually involve aspects such as speed, costs, versatility with respect to feedstock material, geometrical limitations and tolerances, as well as a mechanical and appearance properties of the products such as strength, texture, and color.

Al Hock invited Tom Peer and Dave Lutz to join him in New Hampshire to look into this new venture and they accepted the job offer.

Dave Lutz contacted two jet people still at Exxon, Jim and Kathy McMahon and they also accepted offers to be founders in this venture later to be named Howtek, Inc.

Tefzel allowed the inkjet to work at high temperature with the new Thermoplastic Hot-melt inks and run with no vibrations in the nozzle structure to generate stray drops.

Thermoplastic ink drop printing is accurate and precise giving high quality surface finish models popular with jewelers and detail sensitive CAD designers.

The first printer was sold in 1993 to Hitchner Corporations, Metal Casting Technology R&D group where they printed golf club heads and parts for automobile engines.

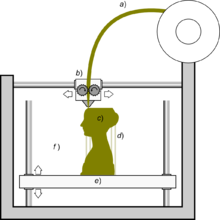

Various polymers may be used, including acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polylactic acid (PLA), high-density polyethylene (HDPE), PC/ABS, polyphenylsulfone (PPSU) and high impact polystyrene (HIPS).

Usually, the software that converts the 3D model into a set of flat layers, called slicer, takes care of the addition of these supports and some other resources to allow the fabrication of this kind of shapes.

[32] Selective Laser Sintering (SLS) was developed and patented by Dr. Carl Deckard and Dr. Joseph Beaman at the University of Texas at Austin in the mid-1980s,[33] under sponsorship of DARPA.

[36][37] Electron beam melting (EBM) is a similar type of additive manufacturing technology for metal parts (e.g. titanium alloys).

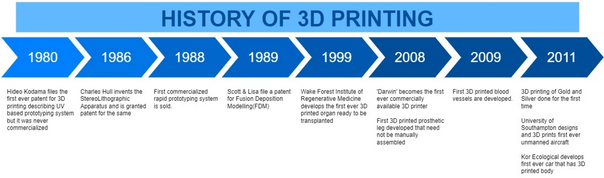

[40] The Stereolithography (SLA) process is based on light curing (photopolymerization) of liquid materials into a solid shape; it was patented in 1986 by Chuck Hull.

[48] In research systems, the light is projected from below, allowing the resin to be quickly spread into uniform thin layers, reducing production time from hours to minutes.

[48] Continuous liquid interface production (CLIP) is another form of additive manufacturing that uses the DLP based photo polymerization process to create smooth-sided solid objects of a wide variety of shapes.

A key innovation in DIP is its dynamic control of the meniscus shape and position via adjustable air pressure and acoustic modulation.

This flexibility enables precise alignment of the interface with the focal plane, improved material transport through capillary-gravity waves, and enhanced resolution.

DIP is container-agnostic and accommodates opaque or biologically relevant materials like PEGDA and GelMA, making it suitable for rapid prototyping, biofabrication, and complex multi-material structures.

Applications include creating detailed biological models, overprinting, and modular particle arrangements, achieved by leveraging acoustic and optical modulation.

During the 1990s some companies marketed printers that cut cross-sections out of special adhesive coated paper using a carbon dioxide laser and then laminated them together.

In 2005 Mcor Technologies Ltd developed a different process using ordinary sheets of office paper, a tungsten carbide blade to cut the shape, and selective deposition of adhesive and pressure to bond the prototype.

LENS (Laser Engineered Net Shaping), is one example of the Powder Fed - Directed Energy Deposition process for 3D printing or restoring metal parts.

[67][68] Low-cost open source RepRap-style 3-D printers have been outfitted with Arduino-based sensors and demonstrated reasonable metallurgical properties from conventional welding wire as feedstock.

[70] As of October 2012, additive manufacturing systems were on the market that ranged from $2,000 to $500,000 in price and were employed in industries including aerospace, architecture, automotive, defense, and medical replacements, among many others.

These types of devices are used widely in industry for prototyping, jig making, fixturing, fixing small custom components, and even additive manufacturing of actual products.

[79] The UCL School of Pharmacy in the UK created a modular flow reactor system for chemical synthesis that can easily be 3D printed in laboratories around the world at low cost.

The RepRap project aims to produce a free and open source hardware (FOSH) 3D printer, whose full specifications are released under the GNU General Public License, which is capable of replicating itself by printing many of its own (plastic) parts to create more machines.

[92] The open source Fab@Home project[93] has developed printers for general use with anything that can be squirted through a nozzle, from chocolate to silicone sealant and chemical reactants.

[98] In addition, several RecycleBots such as the commercialized Filastruder have been designed and fabricated to convert waste plastic, such as shampoo containers and milk jugs, into inexpensive RepRap filament.

In one technique, 3D nanostructures can be printed by physically moving a dynamic stencil mask during the material deposition process, somewhat analogous to the extrusion method of traditional 3D printers.

Programmable-height nanostructures with resolutions as small as 10 nm have been produced in this fashion, by metallic physical vapor deposition Mechanicalpiezo-actuator controlled stencil mask having a milled nanopore in a silicon nitride membrane.