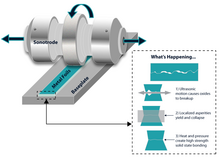

Ultrasonic consolidation

[1] The process works by scrubbing metal foils together with ultrasonic vibrations under pressure in a continuous fashion, i.e., sheet lamination classification in additive manufacturing.

[3][4] CNC contour milling is used interchangeably with the additive stage of the process to introduce internal features and add detail to the metal part.

The file is then "sliced" into layers which results in the production of a cnc gcode file that can be used by the UC machine to build the required object, layer by layer.The general manufacturing process is: Mechanism of the metallurgical bond formation between foils can be explained by microscopic deformation of micro-asperities on the top foil.

The resultant rough imprint on the top foil surface affects bonding of the subsequent layer.

The contact area between the upper and lower foils expands when the micro-asperities are crushed by the ultrasonic oscillations.