ATR 72

Typical updates have included new avionics, such as a glass cockpit, and the adoption of newer engine versions to deliver enhanced performance, such as increased efficiency and reliability and reductions in operating costs.

During the 1980s, French aerospace company Aérospatiale and Italian aviation conglomerate Aeritalia merged their work on a new generation of regional aircraft.

[4] The 2007 production set a new record for the programme's sales; a total of 113 new ATR aircraft had been ordered during a single year.

During July 2004, ATR and Brazilian aircraft manufacturer Embraer announced a co-operation agreement on the AEROChain Portal to deliver improved customer service.

On 8 July 2015, an ATR 72-600 'green' technology demonstrator performed its first flight; the demonstrator was used for testing new composite materials for insulation, air conditioning systems, electrical distribution systems, and energy dispersal modifications to evaluate their effect on the aircraft's overall efficiency as a contribution to the Clean Sky initiative.

During March 2016, a second round of flight trials dedicated the testing of all-electric systems architecture using the demonstrator was completed; analysis is set to continue.

[9] As a consequence of strong demand for the -600 series, ATR decided to invest in the establishment of a second, more modern final assembly line and acquisition of more hangar space at its Toulouse site, along with a new large completion and delivery area; overall, the manufacturing operation expanded to four times the footprint that it had in 2005.

[2] During 2017, a new in-house financing and leasing division was established by ATR in order to offer customers a greater degree of support and expand the company's range of services.

[12] Although expressing satisfaction with the PW127 engine and its supplier, Castelbajac noted the design's age and the need to remain competitive with the latest regional jets.

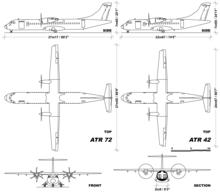

It is powered by a pair of Pratt & Whitney Canada PW100 turboprop engines, which drive an arrangement of four or six-bladed propellers supplied by Hamilton Standard.

[citation needed] While passengers are boarding or disembarking, a tail stand is set into place as standard procedure to guard against the aircraft nose lifting off the ground.

[16] According to ATR's CEO Filippo Bagnato, sales had continued to grow during the Great Recession despite the downturn experienced by most aviation companies as "fuel consumption that can be half that of the alternatives and [with] lower maintenance costs".

[4] By 2013, while the Asia Pacific region had comprised the majority of ATR's sales when geographically ranked; however, orders from Chinese airlines remained elusive; Bagnato ascribed this anomaly to local market conditions dictating the typical use of larger aircraft, as well as a Chinese government policy of imposing high tariffs on the import of foreign-built fixed-wing aircraft.

[13] During late 2014, ATR set up a new office in Beijing and hired several former Airbus sales personnel with the aim of launching the type in the Chinese market.

[22] Both conversions involve complete stripping of furnishings along with the addition of floor strengthening, new window plugs and 9 g restraining nets, six additional longitudinal tracks for added flexibility, and an E-Class cabin; the ULD model can accommodate standard ULD-packaged cargo, such as LD3 containers or 2.2 by 2.7 metres (88 by 108 in) pallets, which were loaded via a large cargo door located on the port forward side.

Undertaken by a range of companies, such as Alenia subsidiary Aeronavali, Texas-based M7 Aerospace; French firms Indraéro Siren and Aeroconseil, Canadian Infinion Certification Engineering, and Spanish company Arrodisa, by October 2012, in excess of one-fifth of all first-generation ATR 42 and ATR 72 aircraft had already been converted to freighters.

[23] Made possible by a negotiated relaxation of international sanctions against Iran, during June 2017, a €1 billion Iranian contract was finalized for the firm 20 airliners and 20 options;[24][25][26] the delivery of the first four aircraft occurred within weeks of the deal being completed.

[30][31] The armed ATR 72 TMPA variant was developed in cooperation with Turkish Aerospace Industries (TAI), and incorporated additional sensors and mission systems to perform its intended combat role.

[35] The Italian Air Force selected the ATR 72-600 MP,[36] designated as the P-72A, to serve as a multirole maritime patrol, electronic surveillance and C4 platform.

The aircraft, called P-72B by Guardia di Finanza,[39] will supplement the GdF's existing force of four ATR-42s in the border surveillance, maritime patrol and search and rescue roles.

[40] On 8 November 2017, FedEx Express launched the -600 cargo variant with 30 firm orders plus 20 options, in a freighter configuration from the factory.

[45] Two sub-types were marketed as the 210 series (-210): the -211 (and with an enlarged cargo door, called the -212) is a -200 with PW127 engines producing 2,750 shp (2,050 kW) each for improved performance in hot and high-altitude conditions.

Other improvements include higher maximum weights and superior performance, as well as greater automation of power management to ease pilot workload.

The main sensors are A tactical display is added to the glass cockpit and can be integrated with INS/GPS positioning systems and IFF transponder.