Wind turbine

As of 2020[update], hundreds of thousands of large turbines, in installations known as wind farms, were generating over 650 gigawatts of power, with 60 GW added each year.

[6] Made of six to twelve sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were used in the gristmilling and sugarcane industries.

The first historical records of their use in England date to the 11th and 12th centuries; there are reports of German crusaders taking their windmill-making skills to Syria around 1190.

Friedländer's windmill and its accessories were prominently installed at the north entrance to the main exhibition hall ("Rotunde") in the Vienna Prater.

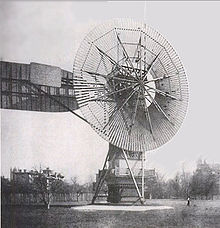

[9][10][11] In July 1887, Scottish academic James Blyth installed a battery-charging machine to light his holiday home in Marykirk, Scotland.

[12] Some months later, American inventor Charles F. Brush was able to build the first automatically operated wind turbine after consulting local University professors and his colleagues Jacob S. Gibbs and Brinsley Coleberd and successfully getting the blueprints peer-reviewed for electricity production.

[8] In Denmark by 1900, there were about 2500 windmills for mechanical loads such as pumps and mills, producing an estimated combined peak power of about 30 megawatts (MW).

Local activists in Germany, nascent turbine manufacturers in Spain, and large investors in the United States in the early 1990s then lobbied for policies that stimulated the industry in those countries.

However, this perspective has been critically dismissed for failing to relay how most wind turbines do not use permanent magnets and for underestimating the power of economic incentives for the expanded production of these minerals.

It is the mean annual power available per square meter of swept area of a turbine, and is calculated for different heights above ground.

Wind-to-rotor efficiency (including rotor blade friction and drag) are among the factors affecting the final price of wind power.

In 2001, commercial utility-connected turbines delivered 75% to 80% of the Betz limit of power extractable from the wind, at rated operating speed.

[31][32] Efficiency can decrease slightly over time, one of the main reasons being dust and insect carcasses on the blades, which alter the aerodynamic profile and essentially reduce the lift to drag ratio of the airfoil.

However, wind turbine wakes have been found to recover faster under unstable atmospheric conditions as opposed to a stable environment.

Despite these advantages, upwind designs are preferred, because the pulsing change in loading from the wind as each blade passes behind the supporting tower can cause damage to the turbine.

[50] The key disadvantages include the relatively low rotational speed with the consequential higher torque and hence higher cost of the drive train, the inherently lower power coefficient, the 360-degree rotation of the aerofoil within the wind flow during each cycle and hence the highly dynamic loading on the blade, the pulsating torque generated by some rotor designs on the drive train, and the difficulty of modelling the wind flow accurately and hence the challenges of analysing and designing the rotor prior to fabricating a prototype.

While wind speeds within the built environment are generally much lower than at exposed rural sites,[52][53] noise may be a concern and an existing structure may not adequately resist the additional stress.

[56] These are drag-type devices with two (or more) scoops that are used in anemometers, Flettner vents (commonly seen on bus and van roofs), and in some high-reliability low-efficiency power turbines.

Because most of these valuable materials are also used in other emerging technologies, like light emitting diodes (LEDs), photo voltaics (PVs) and liquid crystal displays (LCDs), their demand is expected to grow.

[86] A 2011 study by the United States Geological Survey estimated resources required to fulfill the US commitment to supplying 20% of its electricity from wind power by 2030.

[87] Permanent magnets for wind turbine generators contain rare-earth metals such as neodymium (Nd), praseodymium (Pr), terbium (Tb), and dysprosium (Dy).

[90] A few localities have exploited the attention-getting nature of wind turbines by placing them on public display, either with visitor centers around their bases, or with viewing areas farther away.

[91] The wind turbines are generally of conventional horizontal-axis, three-bladed design and generate power to feed electrical grids, but they also serve the unconventional roles of technology demonstration, public relations, and education.

It is the first skyscraper to integrate wind turbines into its design Small wind turbines may be used for a variety of applications including on- or off-grid residences, telecom towers, offshore platforms, rural schools and clinics, remote monitoring and other purposes that require energy where there is no electric grid, or where the grid is unstable.

Hybrid solar- and wind-powered units are increasingly being used for traffic signage, particularly in rural locations, since they avoid the need to lay long cables from the nearest mains connection point.

[94] Small units often have direct-drive generators, direct current output, aeroelastic blades, and lifetime bearings and use a vane to point into the wind.

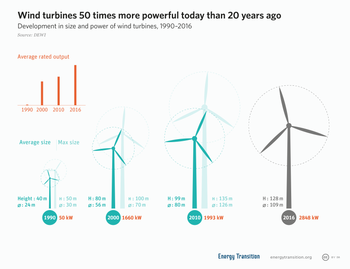

An alternative is repowering, where existing wind turbines are replaced with bigger, more powerful ones, sometimes in smaller numbers while keeping or increasing capacity.

[108] In the United Kingdom, a project will trial cutting blades into strips for use as rebar in concrete, with the aim of reducing emissions in the construction of High Speed 2.

[117] Wind turbines provide a clean energy source,[118] use little water,[2] emitting no greenhouse gases and no waste products during operation.

Over 1,400 tonnes (1,500 short tons) of carbon dioxide per year can be eliminated by using a one-megawatt turbine instead of one megawatt of energy from a fossil fuel.