Alkenylsuccinic anhydrides

Products treated with it show reduced penetration of aqueous media, such as inks or drinks (like milk or fruit juices).

In the United States alkenylsuccinic anhydrides are the preferred paper sizing agents, whereas in Europe, alkyl ketene dimers (AKDs) predominate.

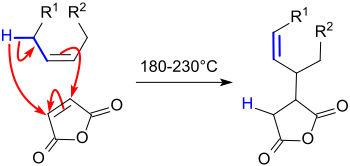

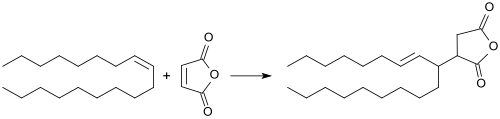

The reaction of maleic anhydride (MA) with aliphatic monounsaturated n- and iso-alkenes was described as early as 1936 in a patent.

30% higher reaction yields were achieved with a pre-cleaned cracked petroleum distillate in an autoclave at 210 °C and it was found that the hydrolysis of the succinic anhydride can already be carried out with steam.

[4] In the early technical applications as lubricants and rust inhibitors, the products dark brown color and black, tar-like polymer residues was unproblematic.

However, for later use in cleaners and detergents, clear (meaning polymer-free) and less dark colored alkenyl succinic anhydride (ASA) were needed.

After initial difficulties in using ASA for paper sizing (particularly the rapid hydrolysis to alkenyl succinic acids and the formation of poorly soluble calcium salts in hard water and deposits in the paper machine), process parameters could be adjusted to make alkenyl succinic anhydrides the most important sizing agents in the US.

Unbranched 1-alkenylsuccinic anhydrides,[9] which can be obtained from 1-alkenes, are solid at room temperature and not suited for engine sizing from aqueous emulsion.

[10] In the SHOP process, even-numbered 1-alkenes (CH2=CH-(CH2)n-CH3, produced by oligomerization of ethylene) are isomerized on magnesium oxide catalysts with displacement of the double bond to a position along the carbon chain.

[12] By combining a reducing agent (such as a trialkyl phosphite) with a phenolic antioxidant, a significant lightening and reduction of tar formation is achieved.

[13] The C12-ASA formed from dodecene and MAN after six hours at 220 °C is light yellow in color but still contains significant amounts of black, tarry decomposition products.

By far the most important use of alkenylsuccinic anhydrides by volume is the surface and bulk sizing of paper and cardboard with a global consumption of approximately 47,000 tonnes (in 2005).

[19][20] These findings suggests that the ASA-induced hydrophobing is rather based on an adsorptive and associative interaction of the alkenylsuccinic acids (formed by rapid hydrolysis in the aqueous medium) with the constituents of the paper pulp (cellulosic fibers and fillers, such as precipitated calcium carbonate or cationic polymers).

Enormous challenges are posed by the trend towards recycled materials paper as raw material (the so-called secondary fibers), the rapid increase in the volume of cardboard at the expense of printing paper, the growing speeds (> 120 km/h[15]) and production quantities (maximum daily capacity of a single machine >4,500 tons or >1.5 million tons per year[21]), the further development of ASA-based sizing agents for cellulose and its formulations.