Alkyd

The term alkyd is a modification of the original name "alcid", reflecting the fact that they are derived from alcohol and organic acids.

[4] These were sold as substitutes for the darker-colored copal resins, thus creating alkyd varnishes that were much paler in colour.

Higher-quality, higher-performance alkyds are produced in the fatty acid process, in which the composition of the resulting resin may be more precisely controlled.

More economical alkyd resins are produced from the alcoholysis or glyceride process, in which end-product quality control is not as paramount.

To remove the water produced as a by-product and to increase the reaction rate, surplus phthalic anhydride is added.

The reaction is not as controllable as would be desired, so a new process was introduced in which xylene is added to produce an azeotrope with the water.

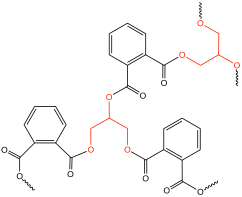

In both cases, the resulting product is a polyester resin to which pendant drying oil groups are attached.

At the conclusion of each process the resin is purified, diluted in solvent and sold to paint and varnish makers.

The alkyd resin is mixed with a polymeric isocyanate and a metallic drier, which speeds up the reaction.

[14] By adding certain modifying resins, it is possible to produce thixotropic alkyds for decorative use such as non-drip paints.

Non-drying/plasticizer resins are made from castor, palm, coconut oils and Cardura[16][17] (the proprietary name of a synthetic ester of versatic acid).

[24] As part of an effort to use more recycled materials, alkyds have been produced that are made from scrap PET bottles.

[29] Synthesis techniques of acrylic-modified water-reducible alkyds to improve corrosion performance have likewise been studied.