Biodegradable polymer

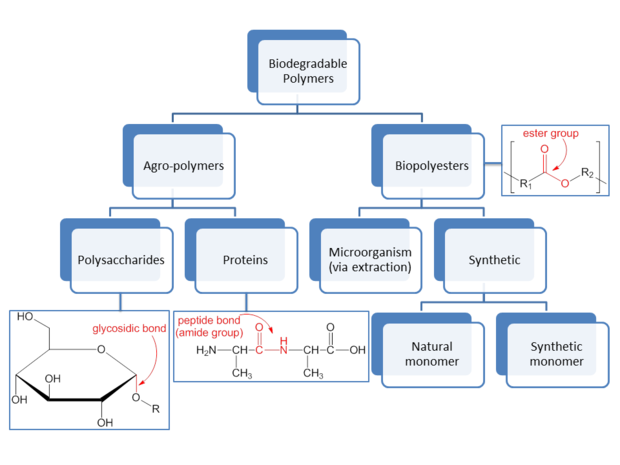

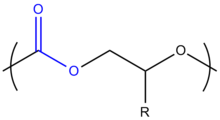

[1][2] These polymers are found both naturally and synthetically made, and largely consist of ester, amide, and ether functional groups.

Bio-based packaging materials have been introduced as a green alternative in the past decades, among which, edible films have gained more attention due to their environmentally-friendly characteristics, vast variety and availability, non-toxicity, and low cost.

[3] Biodegradable polymers have a long history, and since many are natural products, the precise timeline of their discovery and use cannot be accurately traced.

[citation needed] Large clothing and grocery store chains have pushed to utilize biodegradable bags in the late 2010s.

Agro-polymers include polysaccharides, like starches found in potatoes or wood, and proteins, such as animal based whey or plant derived gluten.

Since the degradation begins at the end, a high surface area is common as it allows easy access for either the chemical, light, or organism.

[citation needed] A low degree of polymerization is normally seen, as hinted at above, as doing so allows for more accessible end groups for reaction with the degradation initiator.

Other properties of biodegradable polymers that are common among those used for medicinal usages include being: A goal is not to elicit the immune response, and the products of degradation also need not to be toxic.

The degradation rate depends on the location in the body, which influences the environment surrounding the polymer such as pH, enzymes concentration, and amount of water, among others.

[9] A great disadvantage of the step-wise polymerization via condensation of an acid and an alcohol is the need to continuously remove water from this system in order to drive the equilibrium of the reaction forward.

A wide variety of starting materials can be used to synthesize polyesters, and each monomer type endows the final polymer chain with different characteristics and properties.

[9] Polyanhydrides can be made via a variety of methods also used in the synthesis of other polymers, including condensation, dehydrochlorination, dehydrative coupling, and ROP.

Some fillers are natural fiber reinforcements such as silk nanofibers, bamboo, jute, in addition to nano-clay, and carbon nanotubes as alternatives to name a few.

[16][17] Each of these enhancements have a unique property that not only improve strength, but also processability, through humidity resistance, reduced gas permeability, and have shape memory/recovery.

Some examples, such as the polyhydroxyalkanoates/polylactic acid blend, shows an exceptional increase in the toughness without sacrificing optical clarity, and the copolymer poly(L-lactide-co-ε-caprolactone) has shown shape memory behavior depending on the concentration of poly-ε-caprolactone added.

[citation needed] Typically, after physical processes carry out the initial breakdown of the polymer, microorganisms will then take what is left and break down the components into even simpler units.

[30] A wide variety of non-biodegradable polymers have been used for orthopedic applications including silicone rubber, polyethylene, acrylic resins, polyurethane, polypropylene, and polymethylmethacrylate.

Newer biologically compatible synthetic and natural biodegradable polymers have been developed; these include polyglycolide, polylactide, polyhydroxobutyrate, chitosan, hyaluronic acid, and hydrogels.

For example, poly(L-lactide) (PLA), is used to make screws and darts for meniscal repair and is marketed under the trade name Clearfix Mensical Dart/Screw.

[32] The production of PLA has several advantages, the most important of which is the ability to tailor the physical properties of the polymer through processing methods.

[33] BASF markets a product called ecovio® which is a biobased blend of the company's certified compostable and biodegradable co-polyester ecoflex® and PLA.

[35] Most of these plastics will remain in landfills for years to come or litter the environment posing significant health risks to animals; however, the average person's lifestyle would be impractical without them (see Applications).

Dr. Geoffrey Coates headed research to create catalysts that can not only efficiently create these biodegradable polymers, but the polymers also incorporate the greenhouse gas and global warming contributor, CO2, and, environmentally present ground-ozone producer, CO.[36] These two gases can be found or produced in high concentrations from agricultural waste, coal, and industrial applications as byproducts.

[37] Not only do the catalysts utilize these normally wasted and environmentally unfriendly gases, but they also do it extremely efficiently with high turnover numbers and frequencies in addition to good selectivity.

[37] These catalysts have been actively used by Novomer Inc to make polycarbonates that can replace the current coating bisphenol A (BPA) found in many food and drink packaging.

Novomer's analysis shows that if used in all cases, these biodegradable polymer coatings could not only sequester, but also avoid further production of CO2 in hundreds of millions of metric tons in just a single year.

These organic plants have the chance to be sprayed with pesticides which contain chemicals which can contaminate the crops and be transferred into the final finished product.