Bioreactor

Suspension bioreactors may support a wider variety of organisms, since special attachment surfaces are not needed, and can operate at a much larger scale than immobilized cultures.

[3] It can be applied to basically all types of biocatalysis including enzymes, cellular organelles, animal and plant cells and organs.

[4][5] Immobilization is useful for continuously operated processes, since the organisms will not be removed with the reactor effluent, but is limited in scale because the microbes are only present on the surfaces of the vessel.

The environmental conditions inside the bioreactor, such as temperature, nutrient concentrations, pH, and dissolved gases (especially oxygen for aerobic fermentations) affect the growth and productivity of the organisms.

The action of the rising bubbles helps mix the fermentation medium and also "strips" out waste gases, such as carbon dioxide.

[citation needed] A photobioreactor (PBR) is a bioreactor which incorporates some type of light source (that may be natural sunlight or artificial illumination).

Virtually any translucent container could be called a PBR, however the term is more commonly used to define a closed system, as opposed to an open storage tank or pond.

In some of these systems, a chemically inert medium with very high surface area is provided as a substrate for the growth of biological film.

In other systems aerators supply oxygen to the sewage and biota to create activated sludge in which the biological component is freely mixed in the liquor in "flocs".

In these processes, the liquid's biochemical oxygen demand (BOD) is reduced sufficiently to render the contaminated water fit for reuse.

This poses a challenge when the goal is to culture larger quantities of cells for therapeutic production purposes, and a significantly different design is needed compared to industrial bioreactors used for growing protein expression systems such as yeast and bacteria.

Applications of biochemical engineering cover major fields of civilization such as agriculture, food and healthcare, resource recovery and fine chemicals.

This is done in an upstream processing step which involves chemical hydrolysis, preparation of liquid medium, separation of particulate, air purification and many other preparatory operations.

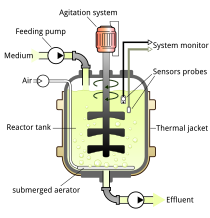

[12] A typical bioreactor consists of following parts: Agitator – Used for the mixing of the contents of the reactor which keeps the cells in the perfect homogenous condition for better transport of nutrients and oxygen to the desired product(s).

Baffle – Used to break the vortex formation in the vessel, which is usually highly undesirable as it changes the center of gravity of the system and consumes additional power.