Boundary Dam Power Station

[15] The retrofitted unit was officially opened in October 2014,[16] and is the world's first commercial-scale, lignite-fired power plant equipped with carbon capture and storage technology[17][18] In 2015, internal documents from SaskPower revealed that there were "serious design issues" in the carbon capture system, resulting in regular breakdowns and maintenance problems that led the unit to only be operational 40% of the time.

SNC-Lavalin had been contracted to engineer, procure, and build the facility, and the documents asserted that it "has neither the will or the ability to fix some of these fundamental flaws.

[26][27] An April 2016 Parliamentary Budget Office report found that CCS at Boundary Dam doubles the price of electricity.

The facility planned to capture 90 percent of total carbon dioxide emissions from Unit 3[41] or one million tonnes annually.

[43] [44] Most of the total annual carbon dioxide capture volume, at least for the first ten years of the project, was sold to Alberta-based Cenovus Energy,[45] the operator of the Weyburn Oil Field.

Cenovus Energy used the carbon dioxide mainly for field injection work to increase crude oil production before its Saskatchewan operations were sold to Whitecap Resources.

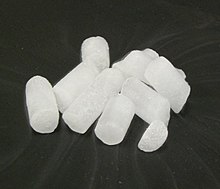

It is now captured by electrostatic precipitators and stored at the point of generation, placed in landfills or recycled - where it will typically replace Portland Cement in concrete production.

Typical fly ash recovery rates, for Saskatchewan lignite-fired power stations, are 31 kilograms per megawatt hour.

In the latter, carbon and sulfur dioxide amine-based capture units, such as the one at Boundary Dam, consume significant amounts of electricity and heat in operation and the largest single component is associated with solvent regeneration.

[51] Significant electrical load is also used to run additional emission control components (e.g. NOx and mercury capture) as well as associated pumps and other equipment.