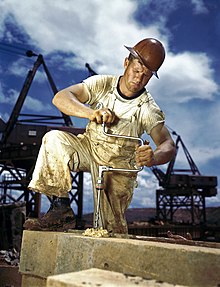

Brace (tool)

The cost of the greater torque is lower rotational speed; it is easy for a geared hand drill to achieve a rotational speed of several hundred revolutions per minute, while it would require considerable effort to achieve even 100 rpm with a brace.

The front of the brace consists of a chuck spindle with V-shaped brackets or clamps inside.

In most modern braces, immediately behind the chuck is a three position gear release that allows ratcheting of the handle when in tight spots.

Turning the gear release from the center position allows ratcheting the brace in the required direction.

The earliest carpenter's braces equipped with a U-shaped grip, that is with a compound crank, appeared between 1420 and 1430 in Flanders.