Computer cooling

A computer with thermal sensors integrated in the CPU, motherboard, chipset, or GPU can shut itself down when high temperatures are detected to prevent permanent damage, although this may not completely guarantee long-term safe operation.

Throttling is also commonly used to manage temperatures in smartphones and tablets, where components are packed tightly together with little to no active cooling, and with additional heat transferred from the hand of the user.

Starting in 1965, IBM and other manufacturers of mainframe computers sponsored intensive research into the physics of cooling densely packed integrated circuits.

The integrated circuits used in the machine were the fastest available at the time, using emitter-coupled logic; however, the speed was accompanied by high power consumption compared to later CMOS devices.

[7] Performance per watt of modern systems has greatly improved; many more computations can be carried out with a given power consumption than was possible with the integrated circuits of the 1980s and 1990s.

Fans may be fitted to the computer case or attached to CPUs, GPUs, chipsets, power supply units (PSUs), hard drives, or as cards plugged into an expansion slot.

The slope of the chassis impedance curve is a square root function, where doubling the flow rate required four times the differential pressure.

An alternating current passed through the ceramic component causes it to expand and contract at up to 150 times per second so that the nickel discs act like a bellows.

A wide variety of liquids exist for this purpose, including transformer oils, synthetic single-phase and dual phase dielectric coolants such as 3M Fluorinert or 3M Novec.

[16] Thermal pastes used to transfer heat to heatsinks from processors and graphic cards has been reported to dissolve in some liquids, however with negligible impact to cooling, unless the components were removed and operated in air.

Heatsinks are usually made of a metal with high thermal conductivity such as aluminium or copper,[20] and incorporate fins to increase surface area.

Passive heatsinks are commonly found on older CPUs, parts that do not dissipate much power (such as the chipset), computers with low-power processors, and equipment where silent operation is critical and fan noise unacceptable.

Modern TECs use several stacked units each composed of dozens or hundreds of thermocouples laid out next to each other, which allows for a substantial amount of heat transfer.

As active heat pumps which consume power, TECs can produce temperatures below ambient, impossible with passive heatsinks, radiator-cooled liquid cooling, and heatpipe HSFs.

[35] (The first major foray into the field of liquid-cooled personal computers for general use, the high-end versions of Apple's Power Mac G5, was ultimately doomed by a propensity for coolant leaks.

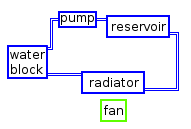

[38] While originally limited to mainframe computers, liquid cooling has become a practice largely associated with overclocking in the form of either manufactured all-in-one (AIO) kits or do-it-yourself setups assembled from individually gathered parts.

The corona discharge cooler developed by Kronos works in the following manner: A high electric field is created at the tip of the cathode, which is placed on one side of the CPU.

The advantages of the corona-based cooler are its lack of moving parts, thereby eliminating certain reliability issues and operating with a near-zero noise level and moderate energy consumption.

[43] Soft cooling is the practice of utilizing software to take advantage of CPU power saving technologies to minimize energy use.

While resulting in lower total speeds, this can be very useful if overclocking a CPU to improve user experience rather than increase raw processing power, since it can prevent the need for noisier cooling.

This tolerance ensures that the processor will have a higher chance of performing correctly under sub-optimal conditions, such as a lower-quality motherboard or low power supply voltages.

Unfortunately, the system requires large pressure drops, due to the small channels, and the heat flux is lower with dielectric coolants used in electronic cooling.

This requires no moving parts, and is somewhat similar to a heat pump, except that capillary action is not used, making it potentially better in some sense (perhaps most importantly, better in that it is much easier to build, and much more customizable for specific use cases and the flow of coolant/vapor can be arranged in a much wider variety of positions and distances, and have far greater thermal mass and maximum capacity compared to heat pipes which are limited by the amount of coolant present and the speed and flow rate of coolant that capillary action can achieve with the wicking used, often sintered copper powder on the walls of the tube, which have a limited flow rate and capacity.)

In a typical installation of liquid nitrogen cooling, a copper or aluminium pipe is mounted on top of the processor or graphics card.

Evaporation devices ranging from cut out heatsinks with pipes attached to custom milled copper containers are used to hold the nitrogen as well as to prevent large temperature changes.

These techniques are often used, in particular, by those who run parts of their computer (such as the CPU and GPU) at higher voltages and frequencies than specified by manufacturer (overclocking), which increases heat generation.

Positive pressure in combination with filtered intake solves this issue, as air will only incline to be exhausted through these holes and vents in order to reach an equilibrium with its environment.

Another way of accommodating large numbers of systems in a small space is to use blade chassis, oriented vertically rather than horizontally, to facilitate convection.

Because data centers typically contain large numbers of computers and other power-dissipating devices, they risk equipment overheating; extensive HVAC systems are used to prevent this.

Constraints specific to laptops include: the device as a whole has to be as light as possible; the form factor has to be built around the standard keyboard layout; users are very close, so noise must be kept to a minimum, and the case exterior temperature must be kept low enough to be used on a lap.