Ceramic engineering

Austrian chemist Carl Josef Bayer, working for the textile industry in Russia, developed a process to separate alumina from bauxite ore in 1888.

The primary requirement for a transparent armour system is to not only defeat the designated threat but also provide a multi-hit capability with minimized distortion of surrounding areas.

Glass-ceramics often contain a crystalline phase which constitutes anywhere from 30% [m/m] to 90% [m/m] of its composition by volume, yielding an array of materials with interesting thermomechanical properties.

[1][5] The traditional ceramic process generally follows this sequence: Milling → Batching → Mixing → Forming → Drying → Firing → Assembly.

[17] These forming techniques are well known for providing tools and other components with dimensional stability, surface quality, high (near theoretical) density and microstructural uniformity.

Tape casting or forming processes are also of increasing interest for other applications, ranging from open structures such as fuel cells to ceramic composites.

Once a roughly-held-together object called a "green body" is made, it is fired in a kiln, where atomic and molecular diffusion processes give rise to significant changes in the primary microstructural features.

Some of the most common involve pressing the green body to give the densification a head start and reduce the sintering time needed.

Actual crack tortuosity is obtained through imaging techniques, which allows for the direct input of deflection and bowing angles into the model.

The model calculates the average strain energy release rate and compares the resulting increase in fracture toughness to that of a flat crack through the plain matrix.

[22] Additional important features of the deflection analysis include the appearance of asymptotic toughening for the three morphologies at volume fractions in excess of 0.2.

Uncontrolled agglomeration of powders due to attractive van der Waals forces can also give rise to in microstructural inhomogeneities.

[11][25] Differential stresses that develop as a result of non-uniform drying shrinkage are directly related to the rate at which the solvent can be removed, and thus highly dependent upon the distribution of porosity.

In addition, any fluctuations in packing density in the compact as it is prepared for the kiln are often amplified during the sintering process, yielding inhomogeneous densification.

[29] Differential stresses arising from inhomogeneous densification have also been shown to result in the propagation of internal cracks, thus becoming the strength-controlling flaws.

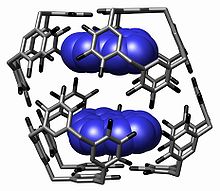

Self-assembly is the most common term in use in the modern scientific community to describe the spontaneous aggregation of particles (atoms, molecules, colloids, micelles, etc.)

[citation needed] The fundamental difference in equilibrium structure is in the spatial scale of the unit cell (or lattice parameter) in each particular case.

This includes an emerging class of mechanically superior biomaterials based on microstructural features and designs found in nature.

There is also substantial interest in dispersion of hard, non-oxide phases such as SiC, TiB, TiC, boron, carbon and especially oxide matrices like alumina and mullite.

Such composite processing has typically been limited to very simple shapes and thus suffers from serious economic problems due to high machining costs.

[36][37] The products of technical ceramics include tiles used in the Space Shuttle program, gas burner nozzles, ballistic protection, nuclear fuel uranium oxide pellets, bio-medical implants, jet engine turbine blades, and missile nose cones.

Recently the field has come to include the studies of single crystals or glass fibers, in addition to traditional polycrystalline materials, and the applications of these have been overlapping and changing rapidly.

The minerals are crystallized from an environment that is undersaturated with respect to silicon, and under conditions of neutral pH and low temperature (0–40 °C).

Most natural (or biological) materials are complex composites whose mechanical properties are often outstanding, considering the weak constituents from which they are assembled.

These complex structures, which have risen from hundreds of million years of evolution, are inspiring the design of novel materials with exceptional physical properties for high performance in adverse conditions.

The 'hard' phases are often strengthened by crystalline minerals, which nucleate and grow in a bio-mediated environment that determines the size, shape and distribution of individual crystals.

Using the classification of Wegst and Ashby, the principal mechanical characteristics and structures of biological ceramics, polymer composites, elastomers, and cellular materials have been presented.

Selected systems in each class are being investigated with emphasis on the relationship between their microstructure over a range of length scales and their mechanical response.

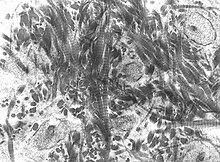

High-resolution scanning electron microscope (SEM) observations were performed of the microstructure of the mother-of-pearl (or nacre) portion of the abalone shell.

Clearly visible in these images are the neatly stacked (or ordered) mineral tiles separated by thin organic sheets along with a macrostructure of larger periodic growth bands which collectively form what scientists are currently referring to as a hierarchical composite structure.