Chain shuttling polymerization

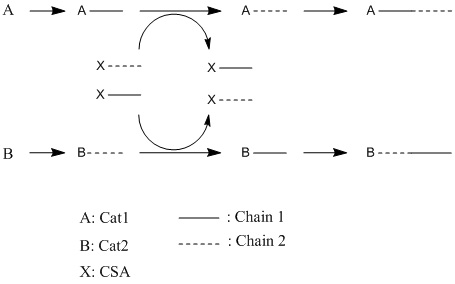

Chain shuttling polymerization is a dual-catalyst method for producing block copolymers with alternating or variable tacticity.

A way to enhance the properties of these olefin polymers was first discovered by the scientists Karl Ziegler and Giulio Natta.

[2] By controlling the tacticity of the polymer, a chain can, for example, either be semi crystalline or amorphous, rigid or elastic, heat resistant or have a low glass transition temperature.

As the forward and reverse reactions occur, the polymer chain is “shuttled” back and forth between the two catalysts and a block copolymer is formed.

The rate of alternation between tacticity can be controlled by altering the concentration of CSA relative to Cat1 and Cat2; having a higher concentration of CSA means that the chains will shuttle back and forth more rapidly, creating shorter units of alternating tacticity.

The technique opens the door for tailor-made polymers to be widely accessible and simple to make inexpensively.